Versatile Vehicle Testing Solution

The DRm™ offers a flexible and adaptable solution for vehicle testing, fitting passenger cars, vans, light commercial vehicles, buses, and heavy goods vehicles. This modular system enhances testing efficiency and reduces costs, making it an essential tool for OEMs and testing facilities. The DRm™ is crucial for meeting the standards of the NCAP Truck Safety Protocol and NHTSA FMVSS 127 ADAS testing.

MODULAR DESIGN

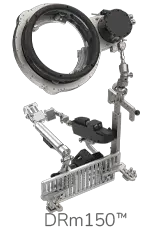

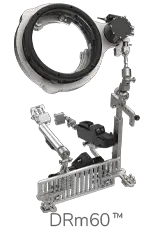

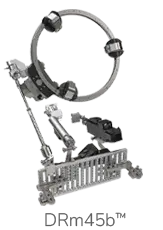

The DRmTM is available in three specialized versions, each tailored to specific vehicle classes and testing demands:

DRm150TM is designed for heavy-duty vehicles such as trucks and buses. It features the high-torque SRm150 steering robot (150 Nm), which mounts onto a Steering Wheel Adapter that supports diameters between 330 and 510 mm.

The system allows for quick, installation with only two tools in under 30 minutes and is ideal for demanding testing scenarios like tight turns, emergency braking, and high-speed maneuvers. The pedal robot (PRm) is mounted on the seat rail, maintaining comfort and foot space, while electronics and battery are secured via ISOFIX or seatbelt systems

DRm60TM is the ideal solution for passenger cars, SUVs, and light commercial vehicles. It uses the SRm60 steering robot (78 Nm) in a modular split design, enabling multiple Vehicle Under Tests (VUTs) to be prepared in parallel using pre-mounted Steering Wheel Adapters.

Like the DRm150TM, it supports quick, installation with only two tools and includes the PRm mounted on the seat rail. The system preserves airbag functionality and allows precise, repeatable control for ADAS validation and development.

DRm45bTM, formerly known as the DRcTM, is a compact, all-in-one solution for passenger vehicle testing. Its integrated actuator unit (45 Nm) is installed behind the original steering wheel, eliminating the need for an external adapter.

This design minimizes intrusion and maintains the vehicle’s original safety systems, including the airbag. The compact electronics box is mounted using ISOFIX, and the system is especially well-suited for situations where space is limited or a fast setup is required.

VERSATILE CAPABILITIES

The DRm™ is a versatile and indispensable tool for ADAS, and truck testing, known for its straightforward installation, and compatibility with multiple vehicle types. The ability to install the DRm™quickly only using one tool significantly reduces setup time and enhances efficiency. Its design allows for rapid switching between Vehicle Under Tests (VUTs) without interfering with the vehicle’s airbag, ensuring safety and ease of use. Comprehensive ADAS testing is crucial for both passenger vehicles and heavy goods vehicles (HGVs) to meet stringent regulatory standards and ensure vehicle safety. The DRm™ is designed to support the NCAP Truck Safety Protocol and NHTSA FMVSS 127 ADAS testing, offering robust, precise control across various test scenarios.

DRm60

DRm150

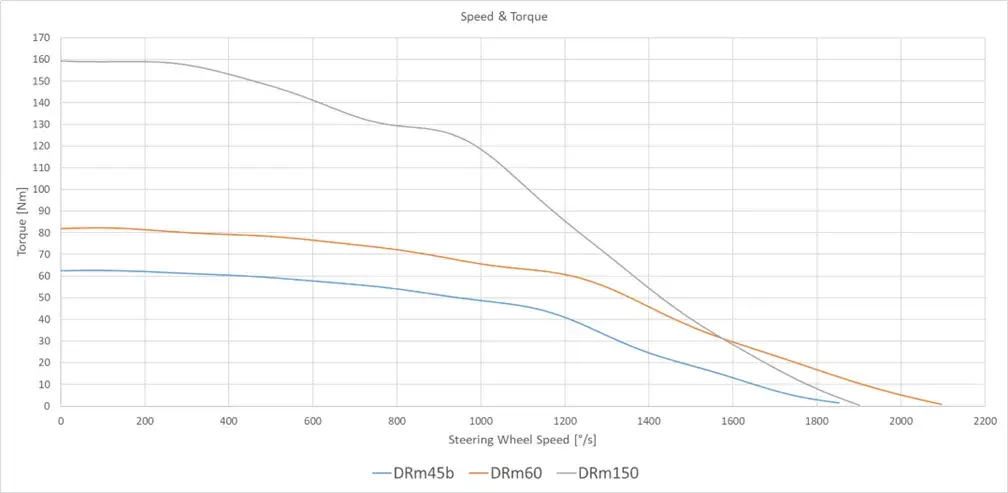

EFFECTIVE TESTING

|

Our DRm™ features high torque for precise control, essential for accurate ADAS testing. It can handle challenging conditions, ensuring reliable performance during tight turns, sudden stops, and varied road scenarios. This capability allows for faithful simulation of real-world driving conditions, including emergency maneuvers and high-speed tests. High torque also enhances stability and safety, making it an indispensable tool for thorough ADAS validation. |

PRODUCT SPECIFICATIONS

| SRm60 | SRm150 | |

|---|---|---|

| Motor | Brushless | Brushless |

| Max Torque | 78 Nm at 400°/s | 150 Nm at 400°/s |

| Steering Wheel Diameter | 330-510 mm | 330-510 mm |

| System Angle Control Accuracy | +/- 0.5° | +/- 0.5° |

| Space in front of Steering Wheel | 60 mm required | 60 mm required |

| Space Behind Steering Wheel | no limitations | no limitations |

| PedalRobot modular™ (PRm™) | |

|---|---|

| Max Continuous Pedal Force | 56 N |

| Max Accelerator Pedal Force | 156 N |

| Max Accelerator Pedal Speed | 1 m/s |

| Max Stroke | 104 mm |

| Control Mode | Speed Control, Position Control, Force Control |

| Security | Safe Design – driver can overrule the brake and take over control at any time |

| Drive Mode | Brushless electric motor |

| Max Braking Force | 1000 N (depending on mounting angle) |

| Max Velocity | 1 m/s |

| Max Stroke | 140 mm (depending on mounting angle) |

| Control Mode | Speed Control, Position Control, Force Control |

SOFTWARE

- ADAS testing

- Automatic Emergency Braking, Car-to-Car / AEB C2C

- Automatic Emergency Braking, Vulnerable Road User / AEB VRU

- Forward Collision Warning, Car-to-Car / FCW C2C

- Forward Collision Warning, Vulnerable Road User / FCW VRU

- Lane Keeping Assist / LKA

- Lane Departure Warning / LDW

- Electronic Lane Keeping / ELK

- Dynamic Brake Support / DBS

- Automatic Emergency Steering / AES

- Emergency Steering Support / ESS

- Rear Automatic Braking

- Blind Spot Detection

- Blind Spot Intervention

- Pedestrian Automatic Emergency Braking

- Intersection Safety Assist

- Opposing Traffic Safety Assist

- Traffic Jam Assist

- And more…

- AV testing

- Customizable traffic scenarios

- Pedestrian protection

- Edge case testing

INSTRUMENTATION

| Motion Data Generation | High precision GNSS unit collects motion data during test execution. |

| Motion Data Output | After each test, the motion data is synchronized and saved into a result file. The user can choose to evaluate the tests based on the generated result file or use the pre-defined evaluation software that Humanetics developed in combination with AVL. |