CAD Analysis and Optimization of Vehicle Interiors for Safety Requirements

Our technology ensures consistent, reproducible, and automated positioning of ATD dummy models. This allows passive safety criteria to be evaluated early in the concept and architecture phase – long before detailed CAE simulations or physical crash testing begin. Streamline passive safety development with precise dummy placement and ensure accurate data transfer to simulation and testing for faster, more reliable safety validation.

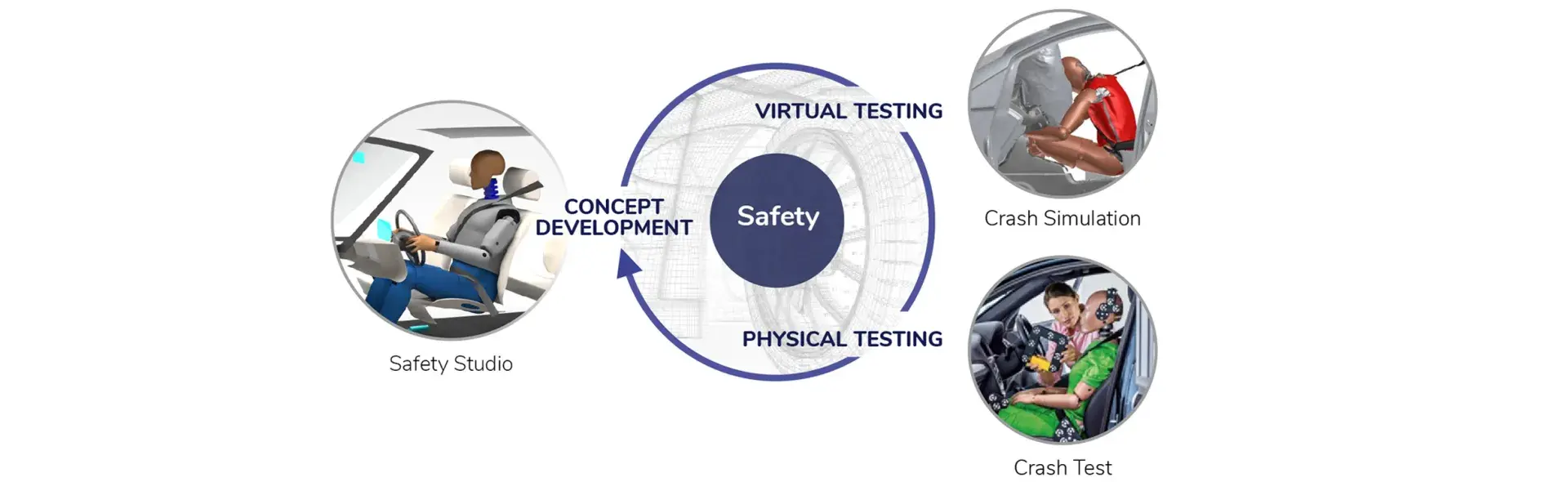

Currently, conceptual development and safety design testing often take place in separate departments using different tools and workflows. This lack of communication can reduce product quality and increase development time. Our integrated CAD tools enable seamless collaboration between engineers throughout every stage of vehicle development. Accelerate Passive Safety Development in the CAD Phase. Improve the efficiency, accuracy, and reliability of your vehicle interior safety design with our solution for automated ATD dummy positioning and interior safety analysis – directly within your CAD environment. Enable seamless collaboration between engineers at all stages of development.

Accelerate Concept Design | Enhance Collaboration | Reduce Design Iterations

Safety Studio Main Features

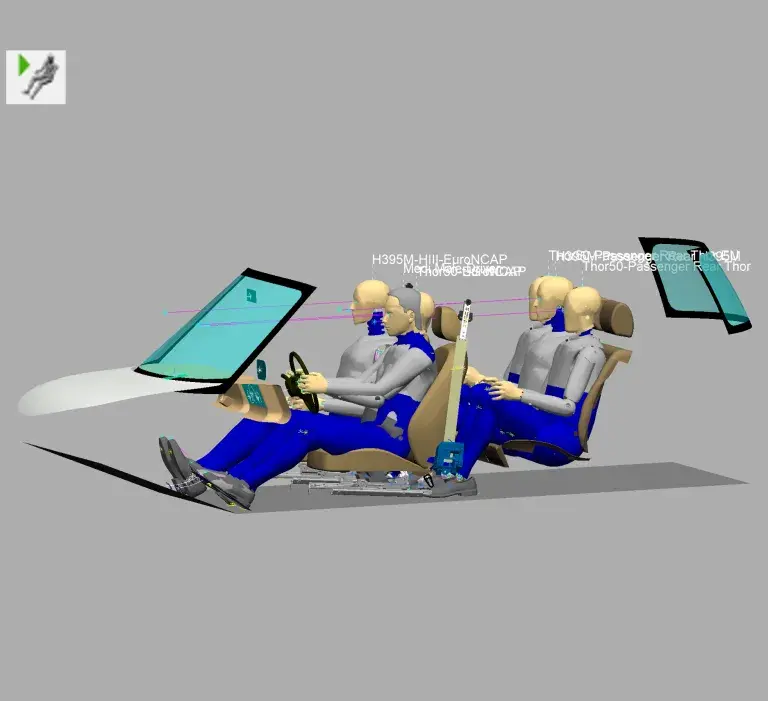

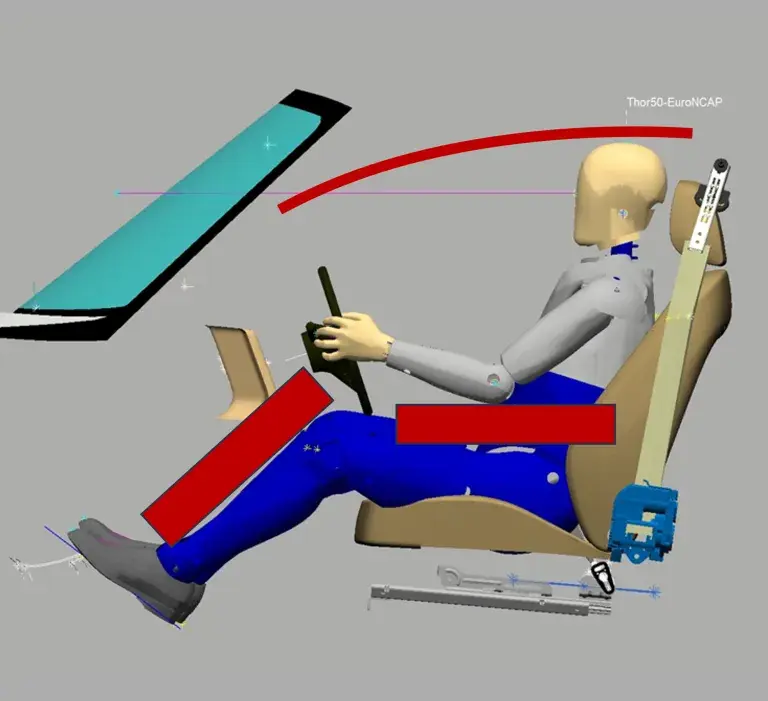

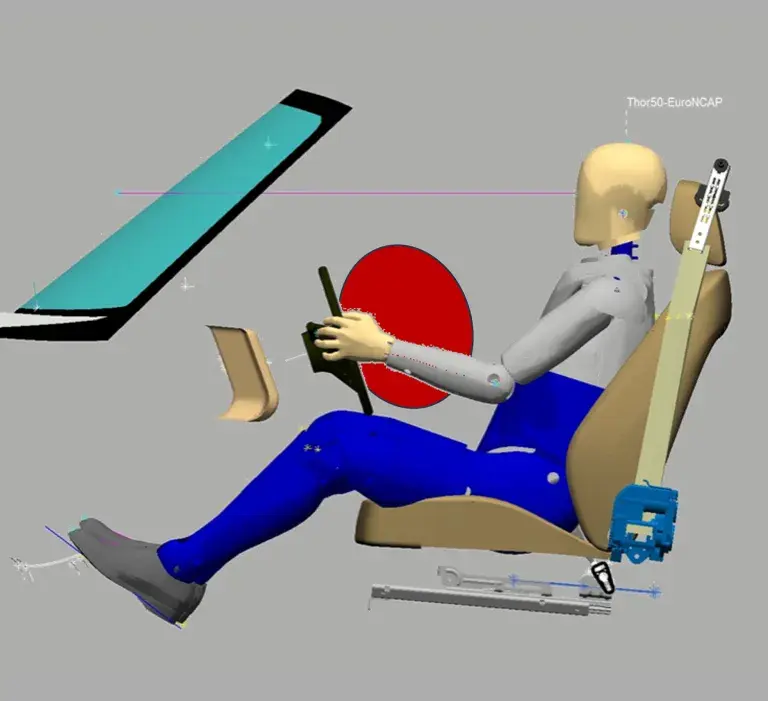

Safety Studio enables comprehensive analysis and optimization of safety-relevant geometries and occupant positioning within vehicle interiors. It allows engineers to analyze geometrical fitting and distance criteria between the interior components and ATD (Anthropomorphic Test Device) models, ensuring that dummies are properly seated in both the first and second rows. The software supports optimization of ATD foot positioning with respect to knee clearance to the center console in the first row or heel distance to the rear seat in the second row, ensuring realistic occupant postures.

Our integrated tools enable seamless collaboration between engineers at every stage of development.

- Interior design analysis and optimization with respect to ATD dummy positions and safety criteria

- Automatic, consistent, and reproducible positioning of ATD dummy models in CAD environments

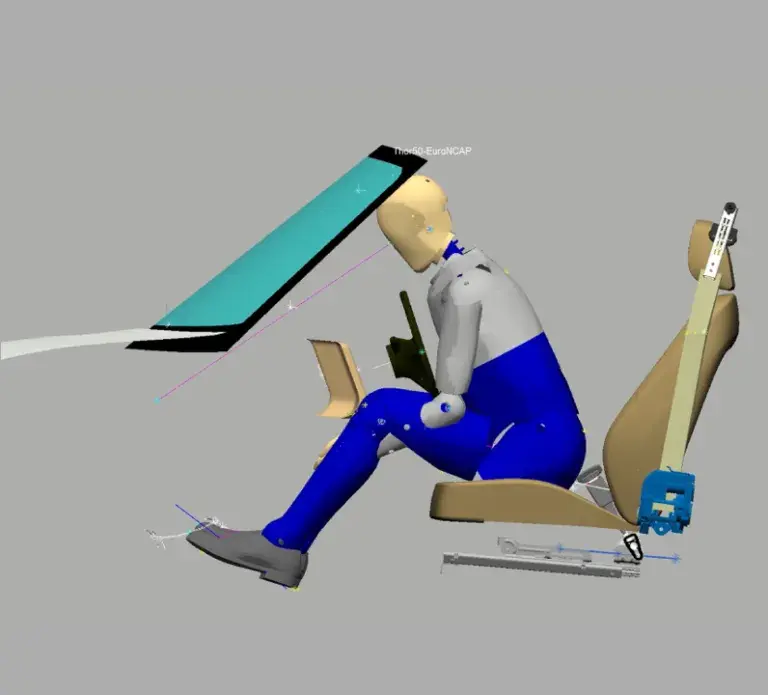

- Bi-directional transfer of ATD dummy posture data between crash simulation (FEM) and testing systems

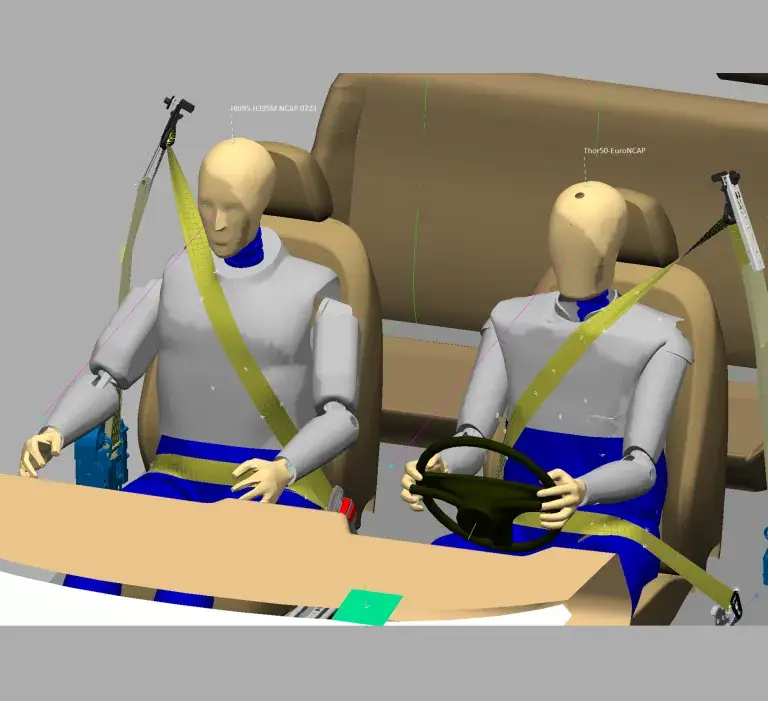

Furthermore, it allows engineers to validate seat belt restraint systems, checking proper belt routing, shoulder fit, and preventing submarining effects during impact simulations. Using automatically positioned ATD models, Safety Studio helps derive safety target surfaces and zones for interior design, supporting compliance with global safety requirements. In addition, updated ATD positions can be synchronized directly in CAD using refined crash simulation data from CAE tools - creating a seamless link between design, simulation, and safety validation.

Enhance your vehicle interior safety design with advanced CAD analysis and optimization tools that ensure accurate dummy positioning according to global safety standards. Achieve greater efficiency in passive safety development during the early concept phase by using automated features to assess and optimize interior safety concepts against established safety criteria. Improve product quality and reduce development time and costs through seamless data exchange between concept design, simulation, and physical testing tools.

Key Benefits

Safety Studio is an innovative solution that allows automotive engineers to consider and validate safety aspects and requirements already in the early design phase. By integrating safety analysis at the beginning of the development process, it ensures that potential issues are identified and solved before they become costly design problems. With Safety Studio, collaboration between package and safety departments becomes significantly more efficient. The tool provides a shared platform that enables seamless communication and data exchange, ensuring that both teams work towards the same safety goals from day one.

Another key advantage is the more accurate and reliable dummy positioning for FEM simulations, resulting in improved analysis quality and realistic crash behavior prediction. This enhances not only the technical precision but also the credibility of safety evaluations. By detecting and resolving safety issues early,Safety Studio helps to save costs and time that would otherwise be spent on expensive and time-consuming design rollbacks due to late-discovered safety problems.

Increased efficiency in vehicle interior safety design during the early concept phase through precise, standards-compliant test device positioning.

Enhanced quality of passive safety concepts using advanced analysis and optimization tools based on key safety criteria.

Higher product quality and reduced development time and costs through effective sharing of consistent test device data between design, simulation, and testing teams.

Use Cases

Speak to an Expert

Fill out the below form and one of our experts will contact you.