In many Anthropomorphic Test Devices (ATD) certification labs, one of the most overlooked systems is also one of the most essential: tracking, maintaining, and certifying crash test dummies. For many labs, that system still lives in a spreadsheet.

Excel might have worked when ATD inventories were small, and testing was straightforward. But as fleets grow more diverse, ATDs become more complex, and certification requirements tighten, spreadsheets start to break down. Files become hard to manage, tracking asset allocation among technicians becomes unreliable, and certification documents go missing. The result is often delayed crash test timelines, not because of a technical failure, but because the right information wasn’t easily accessible.

The Hidden Cost of Spreadsheets

Tracking ATD usage and certification in spreadsheets isn’t just inefficient — it’s risky. Manual logs and scattered files create real-world problems that slow testing, increase costs, and introduce compliance risks.

- No live status – Is that ATD certified, in calibration, or staged for a test? Without real-time updates, the answer depends on whether someone has manually edited a shared file, and whether you have the latest version.

- Fragmented documentation – Certification reports, calibration histories, and inspection notes are often stored in different folders or inboxes, rarely linked to the actual asset record.

- Audit stress – When regulators request documentation, especially for sensitive certification details, teams often scramble to compile information from multiple, unconnected sources.

- Miscommunication – Without a unified system, handoffs between shifts, teams, or locations lead to duplicated work, missed updates, and even test errors.

- Wasted time – Engineers, managers, and technicians spend hours each week searching for files, sending emails, and confirming details that should be instantly accessible.

Spreadsheets are flexible, but they’re fragile. As your ATD fleet grows and testing cycles accelerate, they simply can’t keep up.

What Labs Need

Labs today need more than digital recordkeeping. They need an intelligent, integrated ATD management software built to handle the complexity of modern crash test workflows.

A robust system should provide:

- Real-time asset tracking

- Automated Notifications

- Centralized, searchable documentation

- Audit-ready certification trails

- Fleet-wide scheduling tools

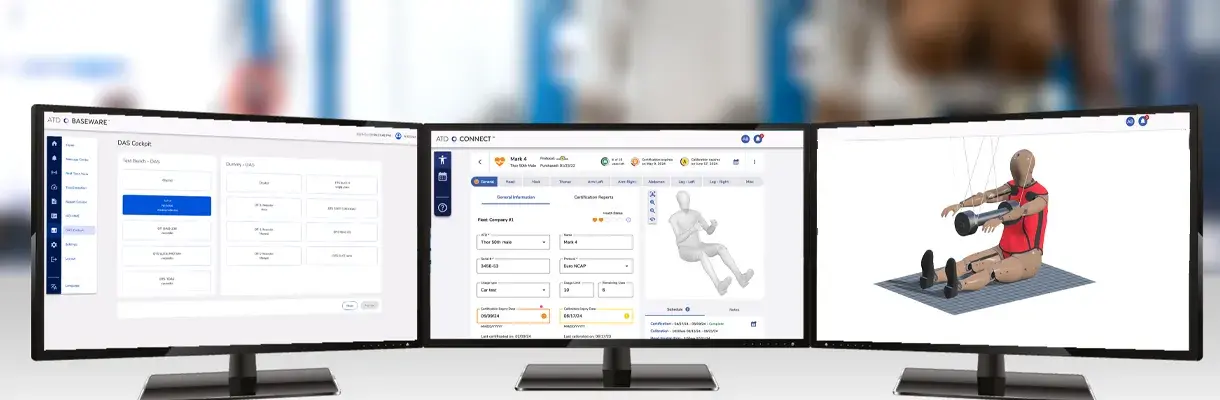

- Data integration with test systems such as ATD-Baseware™ and ATD Management

- Scalable access for multiple lab locations and teams

Together, these capabilities form the backbone of a modern ATD management program, streamlining certification workflows and enabling smarter, data-driven decisions across the fleet.

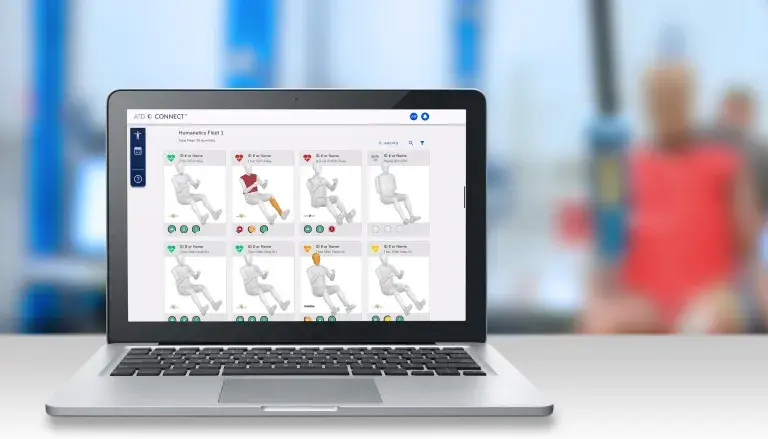

ATD Connect® is one example, a purpose-built platform designed to manage the complete operational lifecycle of ATDs from acquisition to retirement.

What is ATD Connect®

ATD Connect® centralizes all critical data for your ATD fleet, from usage history to certification documentation, and makes it accessible from anywhere.

It’s more than just a database; it’s a live, dynamic, role-based system that helps everyone in the lab, from technicians to managers, see what’s happening and plan the next steps.

As part of the Humanetics Connected Lab, it links physical test hardware to a smarter digital backbone, reducing downtime, improving traceability, and giving labs greater control over their most valuable test assets.

Key Features That Replace Spreadsheets

1. Centralized ATD Fleet Management | No more chasing down emails or digging through folders. ATD Connect® provides a single interface to search and view your entire fleet across your organization, with instant access to critical details such as status, certification records, and upcoming calibration deadlines.

2. Certification and Calibration Records | Every ATD's historical data and certification documentation are stored in one place. Technicians can quickly confirm whether an ATD is test-ready or requires service before deployment, ensuring compliance in any modern ATD certification lab.

3. Integration with ATD-BaseWare™ and ATD Management | ATD Connect® ingests data from test systems such as ATD-Baseware™, linking physical events with digital records. This ensures programs stay connected and data flows seamlessly, allowing labs to use these tools without the usual integration headaches.

4. Document Library and Audit Support | Instead of scattered files, each ATD has a dedicated document library linked directly to its record. Certification documents and test histories are always attached and audit-ready, eliminating the last-minute scramble before a compliance review, with calibration record support coming soon.

5. Global Access, Anytime | As a web-based solution, ATD Connect® can be accessed from any computer, anytime. Whether you're in the lab, at a test facility, or working remotely, you can instantly check an ATD’s status or upload new documentation.

6. ATD Connect® Scheduler | Tool replaces manual spreadsheet tracking using a visual scheduling system. Users can manage events with real-time updates, notifications, and conflict alerts, which ensures tracking where ATDs are and when. This streamlines operations, reduces delays, and improves collaboration.

Whats next: Smarter, AI-Enabled Fleet Tools

ATD Connect® is also designed for the future of crash test equipment management. Upcoming features include:

- Inventory Management – Provides a centralized view of all hardware components and the ability to track, search, and filter all inventory items.

- Diagnostics and AI/ML-driven insights – Providing the ability to flag potential hardware issues before they cause delays.

- Basic Sensor Management – Allows users to add and manage ATD sensors and provides complete visibility into pertinent sensor information, simplifying lab operations by eliminating tracking and allowing for proactive sensor oversight.

- Traceability Logs – Provides a comprehensive log view for all ATD and assembly-related information, offering full transparency, and historical information to support compliance and audit readiness.

- Test Configurator – Allows for customized certification workflows by selecting only what tests apply to your organization for each supported ATD type, eliminating unnecessary testing and allowing for flexibility in testing procedures.

As these capabilities roll out, they’ll offer even more control over lab operations, transforming ATD management from reactive to predictive.

Real-World Benefits For Labs

Labs that have adopted the Connected Lab Test Systems report benefits like:

- Reduced lead time for ATD certification, thanks to improved documentation workflows

- Fewer delays in test scheduling due to better visibility of certified, available dummies

- Lower administrative overhead, no more hunting through folders, sending update emails, or double-checking spreadsheets

- Increased fleet utilization as teams can confidently assign and deploy ATDs based on real-time readiness data

Even small labs benefit from improved traceability and documentation, especially as regulatory expectations grow more complex.

Interested in More Content Like This?

Subscribe to the Humanetics Pulse newsletter to learn more about Humanetics Products, News, and Industry Updates.

Signs It's time to upgrade

If ATD labs are struggling, it’s hard to know when it’s time to look for a new solution. We created a checklist that may help:

- You manage more than a handful of ATDs across multiple locations

- Preparing for audits takes more than a few clicks

- Test delays are caused by uncertainty about dummy readiness

- Multiple teams use different systems (or files) to track the same assets

- Your fleet is growing, and spreadsheets are no longer scaling

The transition is simpler than you might think, and Humanetics can help you integrate ATD Connect® into your existing workflows.

Connected Tools for Connected Labs

ATD Connect® is part of Humanetics’ Connected Lab ecosystem, a digital-first approach that unites hardware, software, and people to meet the demands of modern physical testing. From ATD management software to full-scale test systems, our Connected Lab tools help OEMs, Tier 1 suppliers, and regulators improve test readiness, streamline operations, and keep pace with evolving vehicle safety regulations.

The Future of Dummy Management is digital

Spreadsheets were never designed for complex, high-stakes lab operations. Today’s safety testing environments need smarter tools that match the sophistication of the work they support.

ATD Connect® replaces outdated tracking methods with a centralized, intuitive platform that’s built specifically for managing ATDs. It simplifies compliance, accelerates test readiness, and helps labs plan with confidence.

For teams committed to accuracy, reliability, and innovation, it's not just a software upgrade; it’s a smarter way to work.

Speak to an Expert

Fill out the below form and one of our experts will contact you.

Steven Van Strien

Steven Van Strien is the Senior Director of Product Management at Humanetics, where he leads strategy and development for digital solutions, like the Connected Lab. With over a decade of experience in Software-as-a-Service (SaaS) and software engineering, he brings a technical, customer-driven approach to solving complex challenges and driving product innovation.