Crash safety testing is evolving, and so are ATD labs.

As vehicle development cycles shrink and regulatory requirements grow more demanding, ATD labs face mounting pressure: test faster, minimize downtime, and ensure traceable, compliant data. Traditional tools that once set the industry standard now struggle to keep pace. By linking advanced test systems with intelligent software platforms, the Connected Lab unifies workflows, enhances data integrity, and accelerates decision-making. The result: up to 37% more efficient ATD certification, ISO-compliant reporting, and robust lifecycle management. This isn’t just evolution—it’s the new standard in ATD operations.

The Limits of Traditional Set-Ups

Many ATD certification labs still rely on traditional certification equipment. While these tools have served the industry well for decades, they struggle to meet the demands of modern testing. Manual processes increase the risk of error, data remains siloed, and critical tests must often be repeated due to inconsistencies.

As global protocols expand and more advanced ATDs enter the field, the limitations of legacy workflows become more pronounced. Labs need smarter systems that reduce retest frequency, eliminate paper trails, and provide traceable, ISO-compliant results.

Why Connection Matters

The Connected Lab is more than just a new toolset; it represents a fundamental shift in how certification labs operate. By seamlessly integrating physical test systems with advanced software and data infrastructure, labs can streamline the entire certification process, from test planning to final reporting.

Key benefits of the Connected Lab include:

- Streamline Certification with End-to-End Integration

Connect physical test systems with software and data infrastructure to reduce variability, minimize retests, and accelerate certification from planning through ISO compliant reporting. - Gain Real-Time Visibility and Operational Control

Monitor ATD health, usage, and certification status with tailored metrics. Intelligent scheduling tools help optimize resource allocation and prevent conflicts. - Enhance Compliance and Data-Driven Decision Making

Centralize test data and lifecycle tracking with ATD Connect to ensure full traceability, automate compliance alerts, and support faster, more confident decision making.

Ultimately, certification labs benefit from reduced variability, fewer retests, and streamlined operations, leading to greater efficiency, enhanced compliance, and faster, more confident, insight-driven decision-making across all lab activities.

By consolidating multiple certification procedures into a single, compact system, labs can increase throughput while reducing floor space requirements, equipment needs, and overall lab footprint.

Compact Systems, Greater Efficiency

Next Gen Test Systems do more with less. By consolidating multiple certification procedures into a single, compact system, they help labs increase throughput without expanding floor space. Certification tasks that once required multiple rigs can now be executed on one platform with automated workflows and advanced alignment tools.

- PDC Test System: Head, Neck, Lumbar Spine, Foot, Rib, Abdomen

- Impact Test System: Thorax, Knee, BioRID, FlexPLI, aPLI

- Flex Test System: Lumbar, Pelvis, Thorax

Each test system includes several patented efficiency boosters that facilitate the daily work of lab technicians. This approach minimizes setup changes, and helps maintain a higher throughput rate, contributing to efficiency gains of up to 37% for ISO-compliant ATD certification with our Next Gen Test Systems.

Intelligent Software at the Core

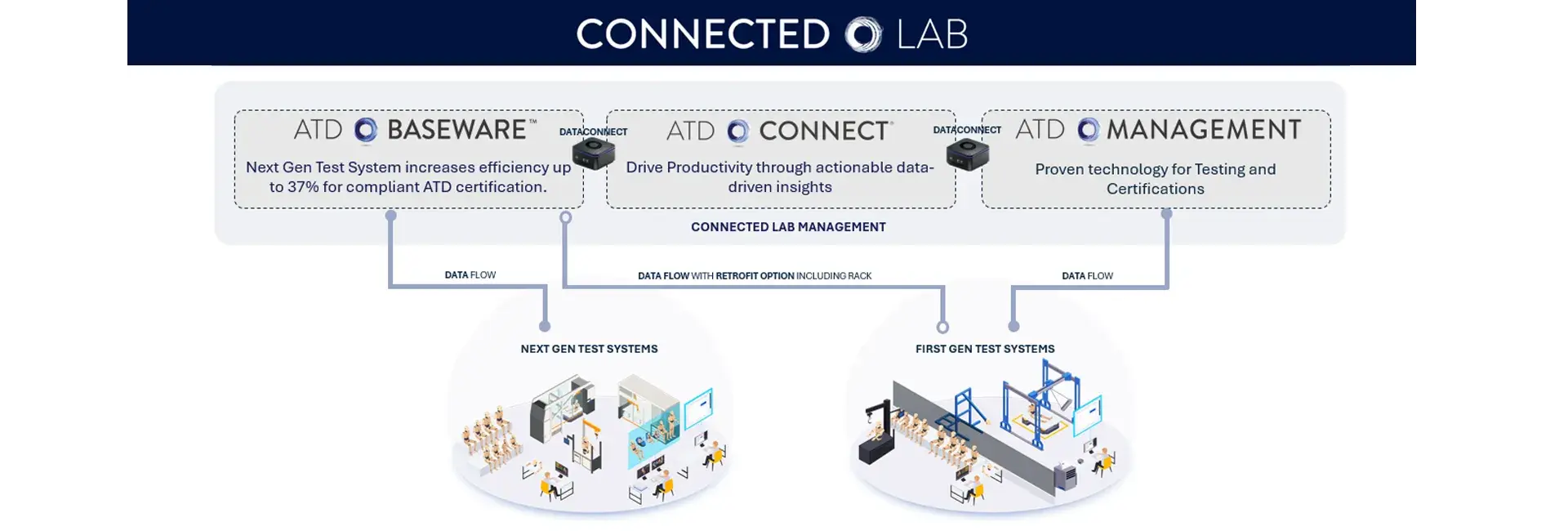

The Connected Lab is built on the synergy between hardware and software. The Connected Lab Management is developed to increase certification efficiency and simplify everyday operations. At the heart of the Connected Lab Management are two key platforms: ATD-BaseWare™ and ATD Connect®.

- ATD-BaseWare™ powers all Next Gen Test Systems. It simplifies and accelerates ATD certification by unifying sensor data, automating workflows, ensuring ISO compliance, and reducing complexity through a single, intuitive platform.

- ATD Connect® streamlines ATD lifecycle management: scheduling, usage tracking, recertification, and conflict resolution. Automated notifications ensure labs are proactively alerted about critical events such as certification expiries, system maintenance, or recertification deadlines.

Together, these tools enable faster onboarding, remote support, actionable analytics, and a consistent compliance framework. All from a single, secure platform.

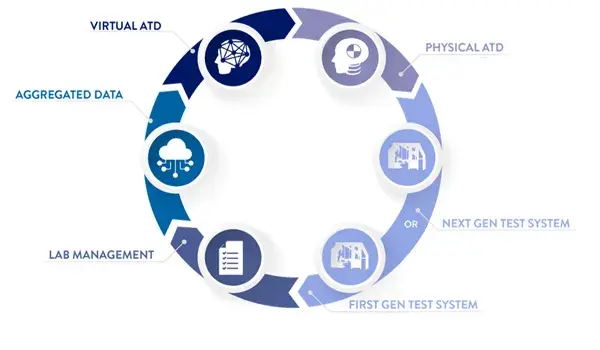

Connected in a Closed-Loop System

At the core of the Connected Lab vision is a seamless loop between physical and virtual testing. Every certification test conducted in the lab generates high-value data that feeds into a real-time digital twin of your ATD. This digital twin can then be used in virtual testing scenarios, enabling more comprehensive analysis, faster iteration cycles, and smarter development decisions.

This closed-loop ecosystem keeps the state of every ATD, whether physical or digital, continuously synchronized. Real-world test data is constantly integrated into virtual models, allowing teams to validate and refine digital ATDs with increasing accuracy and confidence.

Designed for the People Who Use It

While the technology is advanced, the experience is intuitive. The Connected Lab prioritizes usability with ergonomic workstations, guided test sequences, and automation that reduces manual steps. Operators gain clarity and efficiency; managers gain oversight and control.

This focus on human-centered design makes it easier to scale globally, reduce training demands, and standardize certification processes across teams and regions.

Interested in More Content Like This?

Subscribe to the Humanetics Pulse newsletter to learn more about Humanetics Products, News, and Industry Updates.

Retrofitting First Gen Systems

Not every lab can justify immediate full hardware replacement. That’s why we offer retrofit upgrades that preserve your existing investment while modernizing your capabilities. A typical retrofit starts by integrating ATD-BaseWare™ with First Gen Test Systems, allowing labs to unify analog and digital sensor data under one software platform and enable store all certification data in a traceable, tamper-proof format. Additionally, retrofits allow users to:

- Leverage ATD Connect® for lifecycle oversight, analytics, and remote diagnostics

- Achieve ISO-compliant reporting

- Support in-dummy DAS and analog channel integration

- Maintain familiar setups while gaining modern functionality

Retrofits extend the lifespan of proven systems and bring them into the Connected Lab ecosystem with minimal disruption and cost.

More Than Just Technology

The Connected Lab is a core part of Humanetics’ long-term strategy to modernize ATD certification. As OEMs and labs invest in next-gen dummies and infrastructure, they need systems that are faster, smarter, and built for long-term resilience. The Connected Lab delivers just that—integrating test equipment, software, and lifecycle management into a unified, efficient workflow.

It shortens certification cycles with centralized data, and scales easily through secure, cloud-based operations. Continuous software updates keep the system aligned with evolving standards. Real-world test data from ATD Connect® will feed directly into digital models, creating an accurate, real-time digital twin of each ATD. This closed-loop connection between physical and virtual testing strengthens validation, improves traceability, and supports predictive insights.

It’s a future-ready foundation for high-performance labs.

Speak to an Expert

Fill out the below form and one of our experts will contact you.

Steven Van Strien

Steven Van Strien is the Senior Director of Product Management at Humanetics, where he leads strategy and development for digital solutions, like the Connected Lab. With over a decade of experience in Software-as-a-Service (SaaS) and software engineering, he brings a technical, customer-driven approach to solving complex challenges and driving product innovation.