Technology has changed.

Technology has evolved dramatically over the past 50 years, yet crash test safety standards remain anchored in the past. In 1976, the dashing Oldsmobile Cutlass led the best seller charts in the U.S.; in Europe, it was the cute supermini Fiat 127; and Apple launched the Apple 1, with its modest 1 MHz processor and 4KB RAM. Today's iPhones boast processors that are 1,800 times faster and have 500,000 times more memory. Every conceivable facet of technology in our lives has seen decades of relentless, and impactful innovation. Ironically, in the realm of car safety for humans, the Hybrid III "crash test dummy"—also introduced in 1976—still defines the standard of a "human" in US safety regulations. How can we upgrade the vintage crash test dummy still used in the U.S. crash test today? And how can introducing a new generation of advanced crash test dummies, and a digitized end-to-end test ecosystem, drive more efficient vehicle development and safer vehicles?

We're Living in a Digital World

In our digitized world, where innovation has transformed nearly every aspect of life, shouldn't we demand similar progress in automotive safety? With a vision of zero road deaths, embracing cutting-edge technology in safety testing is crucial.

This call for "Safety as a Mission" isn't just about saving lives; it makes economic sense too. Outdated technology leads to inconsistent, variable, and duplicative processes. The automotive industry could significantly reduce costs by streamlining development and testing through digitization, improved process design, and automation.

In an era that has digitized communications, media, content, social interactions, commerce, industrial, energy, defense and medical systems, shouldn’t we demand the same level of innovation and adoption of new technology in the safety industry to address the huge numbers of injuries and fatalities on our roads? If the Vision is zero deaths, then the answer must be a resounding “Yes!”

Evolution of the Crash Test Dummy

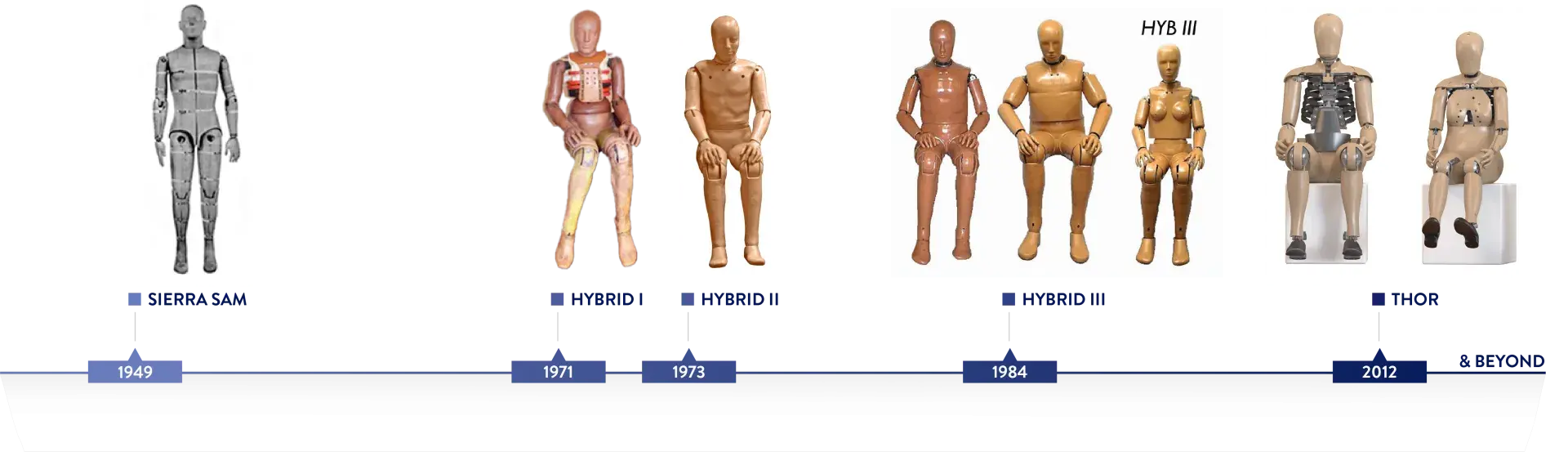

Over the years, crash test dummies have evolved into biofidelic sentient anthropometric test devices. The Hybrid III was the first regulated device to help engineers design vehicles to reduce the huge number of crash fatalities. It was a relatively crude device with sensors placed in places that determined fatal points of impact: the head, the neck, and the chest. It had no sensors in the face, lower legs, pelvis, abdomen or points across the ribs and chest.

The female version of the Hybrid III was a scaled-down, “small” version of the male device, with padded breasts added to the torso. Of course, there have been some minor modifications. Digital sensors now capture the impact data. And the long, cumbersome “umbilical cord” has been replaced in Europe and Asia with tiny data acquisition systems.

The lack of innovation and commitment to continual development in safety standards is contributing to rising injuries and fatalities.

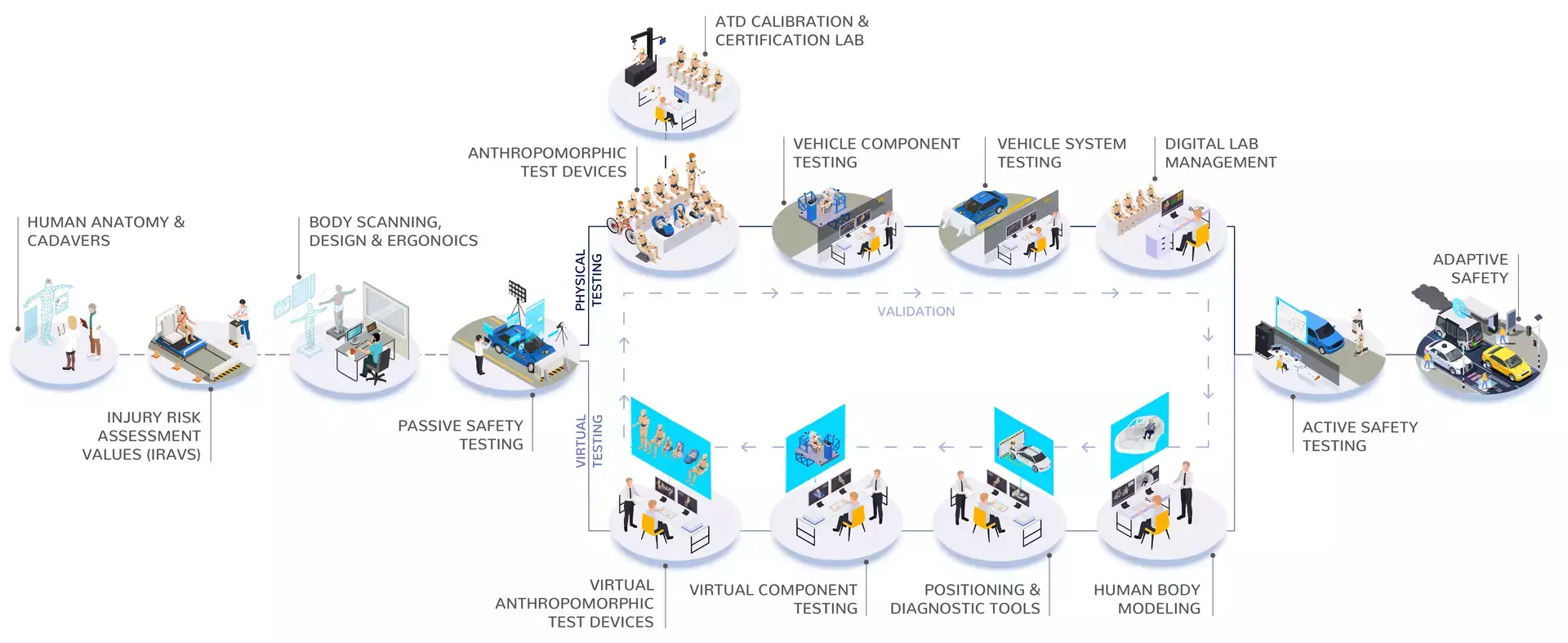

The automotive industry has made significant strides in vehicle safety over the past few decades, largely due to the development and use of Anthropomorphic Test Devices (ATDs), commonly known as crash test dummies. However, as vehicle technology evolves and our understanding of human biomechanics improves, there is a growing need for more advanced ATDs and sophisticated testing methodologies. The introduction of Next Generation ATDs and Connected Lab technologies is set to revolutionize safety testing and management, potentially saving countless lives in the process.

Advanced ATDs, like the THOR (Test Device for Human Occupant Restraint) and WorldSID (Side Impact Dummy) series, represent a significant improvement. These Next Generation ATDs accurately simulate human anatomy and injury responses during crashes. The THOR-5F, for example, can accommodate up to 174 channels of injury sensors, compared to the Hybrid III's 63 channels. Additionally, the THOR-5F features an anatomically correct female pelvis and spine, addressing the underrepresentation of women in vehicle safety testing

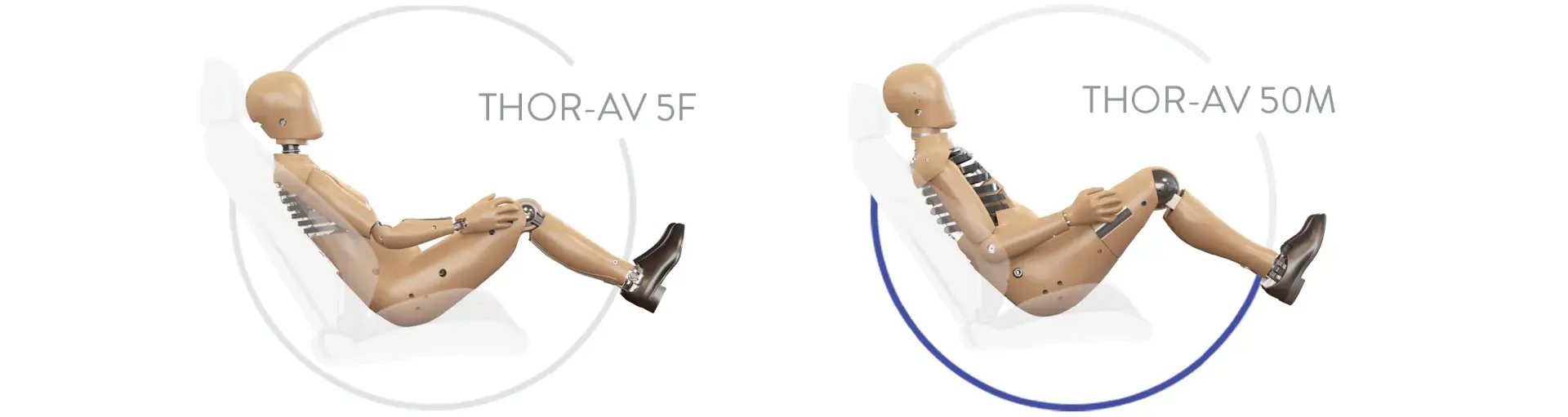

The rise of Advanced Driver-Assistance Systems (ADAS) and autonomous vehicles has necessitated the development of specialized AV test dummies to address new safety challenges. These specialized ATDs are designed to evaluate occupant safety in varied seating positions and directions that may occur in autonomous vehicles where human driver activity is reduced. They can measure forces on the body in altered environments, including reclined seating postures, new neck dynamics, and flexible pelvic structures, making them essential tools for assessing and improving occupant safety in the vehicles of the future.

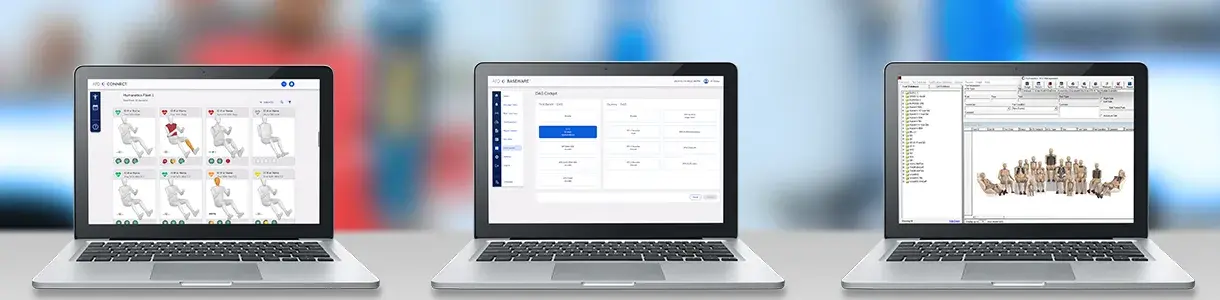

Connecting Digital Laboratory Management

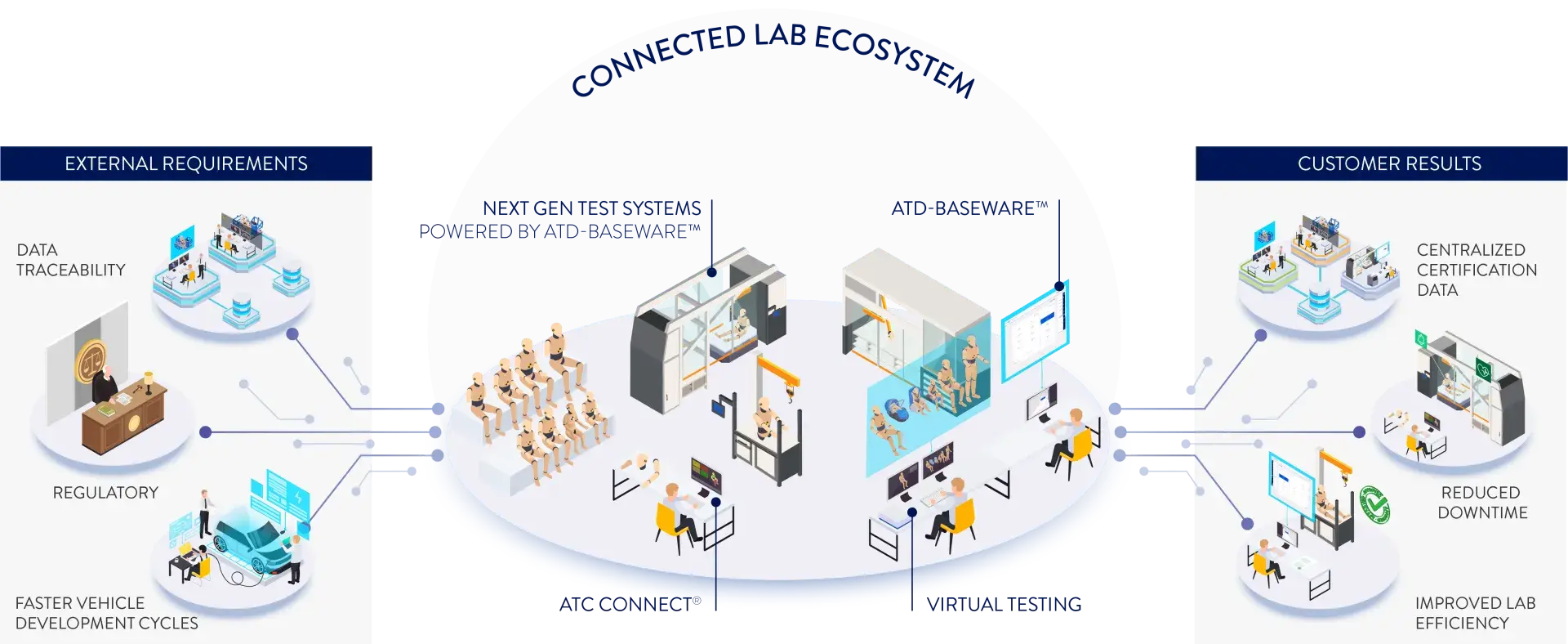

The full potential of these technologically sophisticated ATDs is unlocked when integrated with advanced testing and management systems. This is where Connected Lab technologies come into play. Connected Lab solutions, such as ATD Connect®, ATD-BaseWare™, and ATD Management™, work in tandem to streamline laboratory operations, reduce downtime, and enhance test result consistency.

ATD Connect® serves as the central hub for data acquisition and monitoring, overseeing the entire lifecycle of ATDs from physical testing to continuous fleet monitoring. This system allows lab managers and technicians to easily track the status of their ATD fleet, including test usages remaining, days until the next certification, and sensor calibration schedules. By providing a comprehensive view of the ATD fleet, ATD Connect® enhances operational efficiency and ensures that all ATDs are properly maintained and calibrated for optimal performance.

ATD-BaseWare™ complements ATD Connect® by providing a platform for efficient data management and integration within testing labs. This software automatically processes data acquired from ATDs and their sensors, generating standardized ISO-MME data. The closed-loop process ensures that data output is repeatable and reproducible, which is crucial for consistent and reliable test results.

Facilitating the Digital Twin

The combination of Next Generation ATDs and Connected Lab technologies facilitates the creation of "real-time digital twins" of crash test dummies. This bridge between physical testing and computer-aided engineering (CAE) simulations offers several benefits, including significant reduction in vehicle development time and costs, maintenance or improvement of safety standards, and enhanced ability to address complex vehicle designs and emerging technologies like autonomous driving systems

Economic and Safety Implications

The adoption of these advanced technologies promises substantial benefits. Potential impacts include reduced development and testing expenses for manufacturers, a potential decrease in healthcare costs due to improved vehicle safety measures, and a projected reduction in road fatalities with the implementation of new technology.

Challenges and Considerations

While the benefits are clear, implementing these new technologies comes with challenges. These include initial costs for automotive manufacturers to adopt new testing methodologies, regulatory hurdles in updating safety standards, and the need for industry-wide training and adaptation to new systems.

Striving Towards Vision Zero

As we strive towards a vision of zero road deaths, embracing cutting-edge technology in safety testing is not just crucial, it's imperative. The integration of Next Generation ATDs and Connected Lab technologies represents a paradigm shift in vehicle safety testing and management. By providing more accurate injury data, streamlining laboratory operations, and bridging the gap between physical and virtual testing, these innovations are set to raise the bar for injury prevention.

The automotive industry stands at the threshold of a new era in safety. By adopting these advanced technologies, we can ensure that our vehicles become as sophisticated in protecting lives as our smartphones are in connecting them. The road to zero fatalities is paved with innovation—it's time we accelerate our journey along it.

UP NEXT: Can the same level of innovation and adoption of new technology that protects us inside the car help address the huge numbers of injuries and fatalities on our roads?

Our 'Safety as a Mission' article series covers several key topics in advancing safety technology to save lives. Click the articles below to continue reading about 'Safety as a Mission:

- Part 1: Embracing the Integrated Ecosystem

- Part 2: Our Shared Mission is to Prevent Millions from Dying

- Part 3: A Vision Inspires Hope. A Mission Demands Action

- Part 4: Equitable Design: Design for Every Body

- Part 5: Pedestrians Take a Hit

- Part 6: Next Generation ATDs & the Connected Lab

- Part 7: Welcome to the Proving Grounds: Smart Testing for Crash Prevention

- Part 8: Partnership as an Accelerator: The Agile Model of Development

- Part 9: Conclusion: Safety as a Mission: The Need for Action.

Want to Read More?

Subscribe to the Humanetics Pulse newsletter to learn more about safety as a mission and the full ecosystem.

Barney Loehnis

Barney is the President of Humanetics Sensors & Chief Marketing Officer, leading our Sensor group and marketing growth programs, strategic communications, and customer experience design. He has led marketing and digital transformations in Europe, Asia and the USA in B2B, B2C and agency sectors, for clients like IBM, VW, Huawei, Qualcomm and Mercer Consulting. Barney is a British and American citizen, a bad runner and avid cook.