The Automotive Industry’s Hidden Pressure Point

The automotive industry is in a race against time. The relentless drive to innovate, meet tightening safety standards, and launch vehicles faster is stretching engineering team to their limits. For those responsible for occupant protection—whether working in restraint systems, crash simulation, or CAE validation—the challenge is the same: too much complexity, too little time, and far too many unknowns.

Late-stage injury overshoots, missed NCAP thresholds, and delayed design freezes are no longer isolated issues; they’ve become symptoms of a deeper problem. The industry is pouring time and money into finding out what failed, when the real competitive edge lies in understanding why.

Safety Is Drowning in Data, Not Insight

Modern crash and restraint simulations generate terabytes of data. Yet many engineers still describe the process as “educated guesswork.” When a dummy injury value exceeds NCAP limits, simulation teams are often left guessing: Was it a delayed pretensioner? A high belt load limiter? Posture-related misalignment?

Traditional CAE tools reveal what happened, but not why. That missing cause-and-effect visibility traps teams in time-consuming manual analysis—and the resulting fixes may not be fully effective, triggering several loops of re-iteration. Each iteration adds cost, delay, and risk to launch readiness. One experienced restraint engineer put it bluntly:

We see the HIC or chest peak but rarely know why.

In an environment where every day of delay can jeopardize a launch, this reactive approach is unsustainable. The challenge is clear: your tools show you results—but not reasons. And that gap is costing you time, confidence, and credibility.

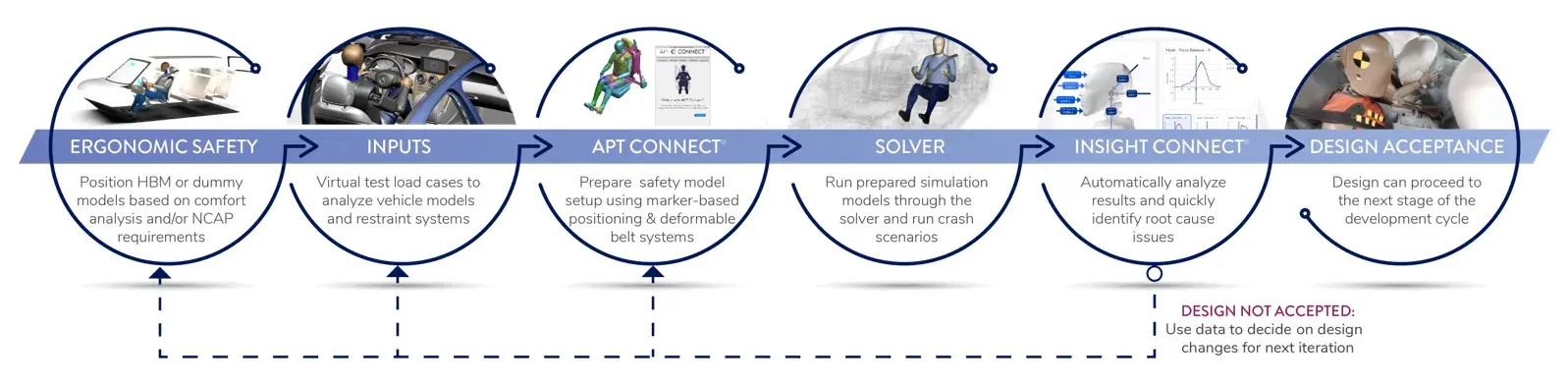

The New Safety Challenge: Designing for Everyone

A restraint system must protect all occupants—men, women, children, the elderly, and heavier individuals. Achieving that universality is a daunting task. A system that performs perfectly for a mid-sized male may become unsafe for a smaller female or a child.

Because airbags and seatbelts rely on precise timing and interaction, even subtle differences in body size or posture can alter how forces are absorbed. Engineers repeatedly adjust restraint performance across population variants, only to find that improvements for one occupant type can worsen performance for another.

The result? Costly re-tests, delayed approvals, and—in some cases—safety or compliance risks. As one engineer observed:

The load limiter worked perfectly for the mid-sized male, but when we added the small female and 10-year-old occupant into the evaluation, the chest injury risk showed exceedance for the 10-year-old child.

As occupant diversity increases and NCAP testing grows more complex, traditional simulation workflows can’t always scale.

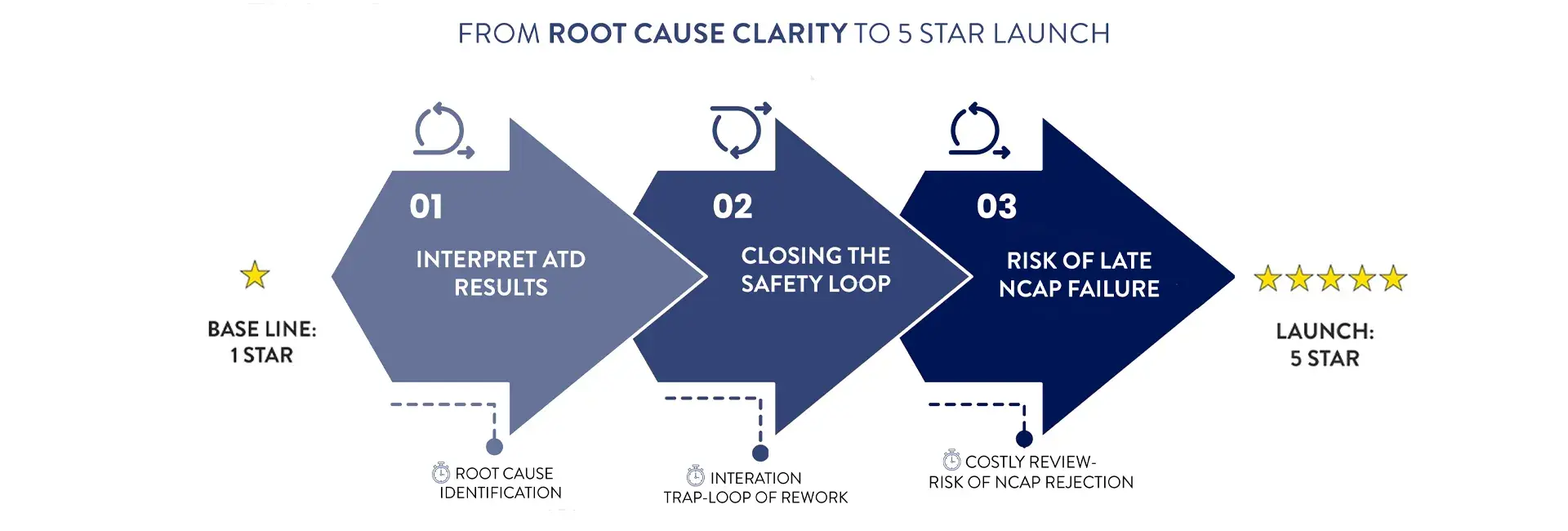

Breaking the Cycle: From Reactive to Predictive Engineering

Design, simulation, and validation cycles are often slowed by inefficiencies and rework. CAE engineers must constantly explain their results to non-CAE stakeholders—vehicle safety managers, test leads, or executives—who may not easily interpret injury metrics. This communication gap leads to repeated decision loops and further delays.

Meanwhile, the lack of diagnostic clarity forces senior experts to spend hours guiding junior engineers rather than improving methods. If key experts are unavailable, project timelines stall.

The question for today’s engineering leaders becomes unavoidable:

What if you could automatically identify which part of the restraint system contributed most to an injury metric—and understand how to fix it?

That’s the shift from reactive troubleshooting to predictive insight.

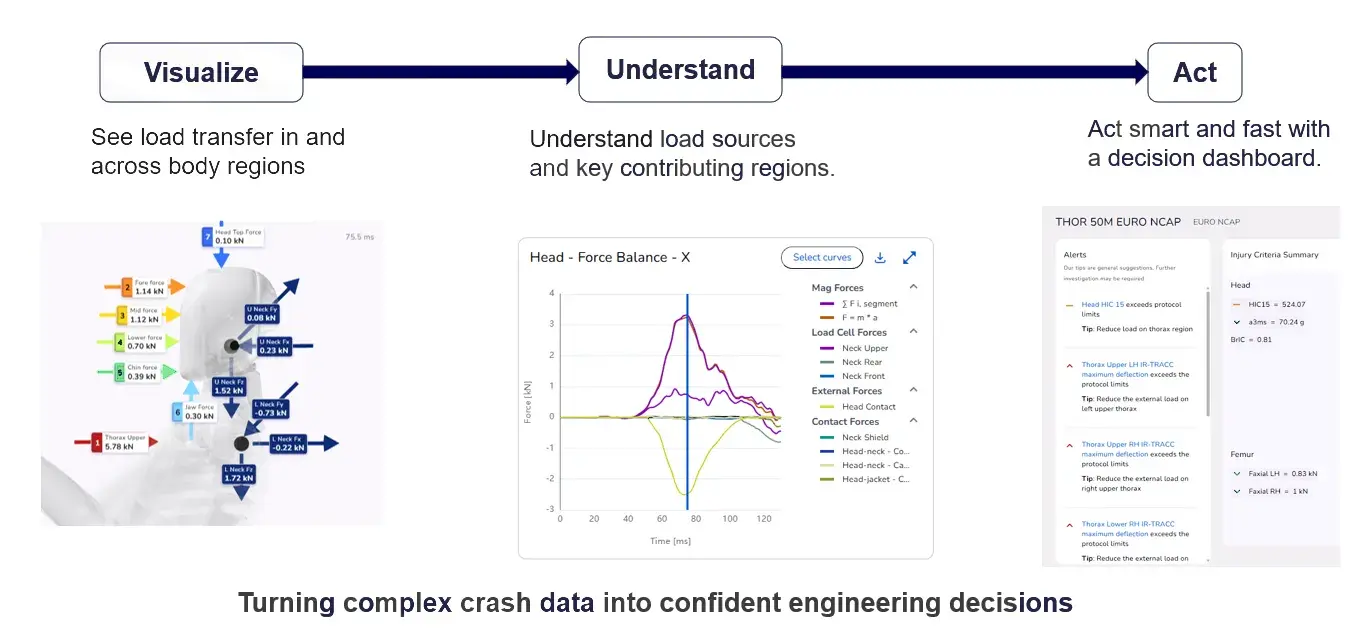

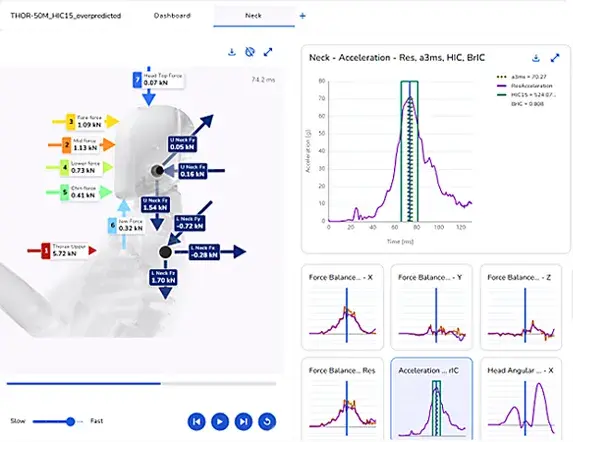

INSIGHT CONNECT®: Turning Data into Decisions

This is where Humanetics’ INSIGHT CONNECT® redefines the process. Built for both restraint and safety simulation engineers, INSIGHT CONNECT® automates root-cause discovery in occupant safety analysis—helping teams pinpoint the why behind dummy injury overshoots in minutes instead of days.

Its strength lies in automated force-vector visualization, a powerful diagnostic feature that maps how crash forces move through the dummy and restraint system. Engineers can instantly see which body regions or components drive injury peaks—and understand precisely how to correct them.

Measured Impact:

- Up to 56 days saved per vehicle program through automation.

- 50–60% time savings across design–simulation–test loops.

- Up to 96 days of total engineering effort reduced for a four-person safety team.

- 21 additional days saved by avoiding false root-cause tracing.

By eliminating guesswork and enabling clear, data-driven decisions, INSIGHT CONNECT® gives teams back control over both time and technical confidence – helping them move from reactive troubleshooting to proactive engineering.

Interested in More Content Like This?

Subscribe to the Humanetics Pulse newsletter to learn more about Humanetics Products, News, and Industry Updates.

Unifying Restraint and Simulation Teams

Safety simulation has outgrown its silos. Engineers validating airbag deployment, restraint interaction, or full-vehicle crash performance all need a common language of causality. INSIGHT CONNECT® provides exactly that.

Fully aligned with emerging NCAP Virtual Testing (VT) standards, the platform helps teams meet future requirements without increasing cost or effort. It identifies whether an injury overshoot stems from a single component—such as a pretensioner—or a complex interaction between multiple restraint elements.

By quantifying load paths and showing how forces act on each body segment, the platform bridges technical and managerial discussions. Engineers gain rapid diagnostic confidence, while decision-makers gain clarity they can act on.

In practice, this unified visibility turns CAE results into actionable narratives—accelerating internal approvals, shortening iteration loops, and ensuring compliance confidence long before physical testing begins.

The Future Belongs to the Curious, Not the Comfortable

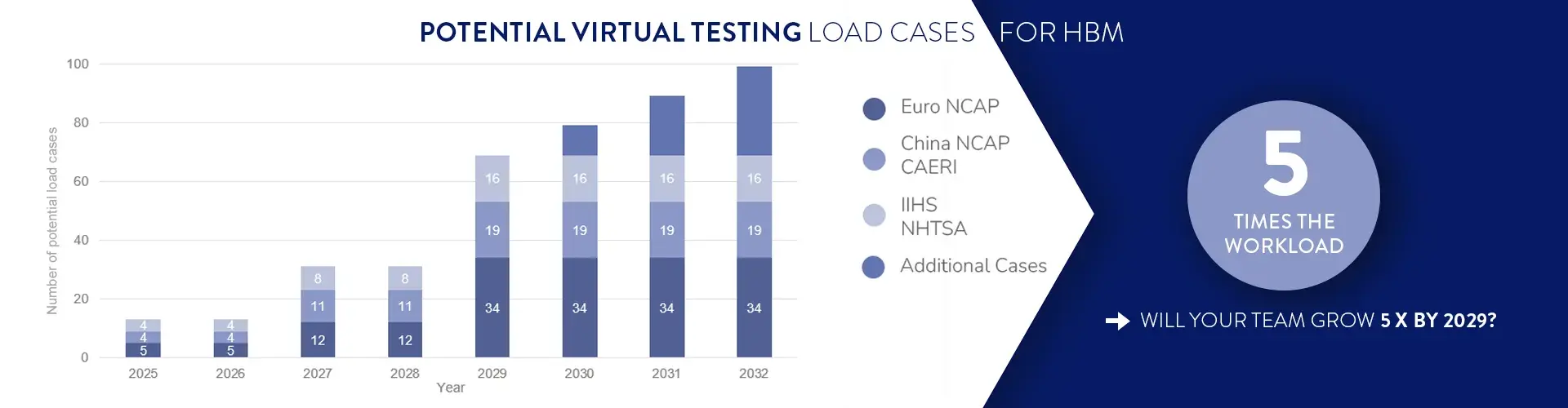

The luxury of time is gone. With safety workloads projected to increase fivefold by 2029, automation isn’t optional—it’s essential. Teams that continue relying on manual analysis will face escalating costs, delayed launches, and mounting regulatory risk.

The future of safety belongs to organizations that use data intelligently—not just to verify results, but to understand why those results occur.

INSIGHT CONNECT® doesn’t replace engineers—it elevates them. It empowers experts to focus on higher-level system design while giving newer engineers access to expert-grade diagnostics and visualization. The result is a culture of speed, confidence, and collaboration—backed by data clarity that drives smarter decisions.

Key benefits Summary

- 50–60% faster design–simulation–test loops

- Up to 56 days saved per program through automation

- Clear visualization of force paths and injury sources

- Expert-level diagnostics for all engineers, regardless of experience

- Compliance-ready for NCAP and Virtual Testing protocols

- Bridges engineering and management with clear, actionable insight

The automotive industry no longer rewards those who react the fastest—it rewards those who see the clearest. As safety complexity grows, insight will become the true competitive advantage in decision-making.

INSIGHT CONNECT® gives simulation and restraint engineers that advantage—turning massive amounts of data into meaningful action, cutting analysis time in half, and future-proofing development processes for the next generation of NCAP standards.

It’s not just about smarter simulations. It’s about smarter safety.

Speak to an Expert

Fill out the below form and one of our experts will contact you.

Apoorva Lakshminarayana

Apoorva is the CAE Product Manager at Humanetics, where he oversees the development and integration of advanced digital human models used in virtual testing and safety simulation. Before stepping into this role, he served as Lead Project Manager, responsible for the development of child and side impact dummy models, contributing to key innovations in occupant safety. With a strong background in computational modeling and biomechanics, Apoorva focuses on bridging physical testing and virtual validation to advance the accuracy and efficiency of safety system development.