When people step into a car, climb into a cockpit, or take command of a ship’s bridge, they bring with them the same expectation: that space will allow them to perform at their best.

Yet meeting that expectation is one of the most complex engineering challenges across industries.

Automotive companies must design vehicles for drivers and passengers across a wide spectrum of ages, genders, and body types. Defense organizations need to ensure pilots, soldiers, and operators can perform flawlessly in high-pressure environments. Shipbuilders are responsible for designing interiors where crews may spend weeks or months at sea, often in confined quarters.

Across all these industries, the problem is the same: traditional design approaches often fail to capture the true diversity of human bodies and behaviors. Relying on a “standard” model or average-sized test subject can lead to blind spots. These oversights may result in uncomfortable seating, unsafe reach distances, obstructed visibility, or even physical injury over time.

The stakes are high. Ergonomics is not a secondary consideration. It is fundamental to safety, mission readiness, and inclusivity.

Automotive: Inclusive Mobility in the Age of Transformation

The automotive industry is undergoing a transformation. Electrification, autonomous systems, and new cabin layouts are rewriting the rules of interior design. But the challenge of making vehicles fit everyone remains.

Designing for inclusivity is more than a marketing slogan; it is a necessity. Around the world, drivers differ not just by height, but by weight, proportions, posture, and cultural expectations. A seat adjustment that works for a tall driver in Germany might not accommodate a shorter driver in Japan. Without the right tools, these variations can be overlooked until late-stage testing or even after a vehicle has reached customers.

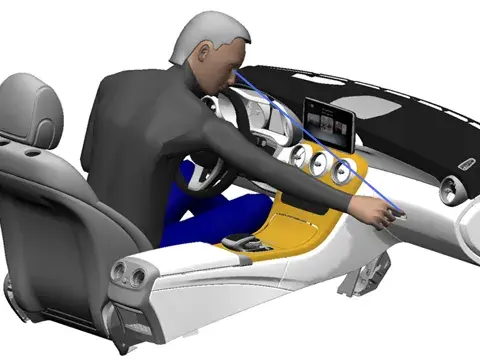

RAMSIS helps automakers address these challenges early in development. Using the world’s most comprehensive database of body measurements, the software creates digital occupants that represent global diversity. Engineers can simulate how men, women, and children of different statures enter, sit, reach for controls, and view the road. Designers can identify potential blind spots in sightlines, optimize dashboard layouts, and test ingress and egress scenarios, all without building a single prototype.

The benefits extend beyond ergonomics. By identifying risks before a physical build, automakers reduce the need for repeated prototype cycles, which can save millions in development costs. RAMSIS also supports compliance with global safety standards by validating visibility and comparing these metrics against regulatory requirements. For manufacturers entering new markets, the ability to simulate regional body data can mean the difference between launching a vehicle that feels natural to local drivers and one that alienates potential customers.

As mobility expands to ride-sharing fleets and autonomous pods, inclusivity is becoming a design imperative. These vehicles must accommodate a far broader set of users than privately owned cars, where individuals often “adapt” their posture to fit. RAMSIS allows designers to anticipate and eliminate those compromises, ensuring mobility is truly accessible for every body.

Another important dimension is sustainability. Each physical prototype that is avoided through digital ergonomics saves not only time and cost but also material resources. By shifting more of the validation process into the virtual domain, manufacturers reduce waste and improve their environmental footprint. This efficiency is becoming a strategic advantage as automakers face pressure to accelerate development cycles while meeting ambitious sustainability goals.

Defense: Ergonomics as a Mission-Critical Factor

In defense, ergonomics is more than comfort; it can mean the difference between mission success and failure.

Fighter jet cockpits, ground vehicle interiors, and control stations are some of the most complex and tightly constrained environments in design. Operators may be wearing bulky protective gear, carrying equipment, or performing under extreme physical and mental stress. Poor ergonomics can slow reaction time, reduce situational awareness, or increase fatigue, all of which carry potentially life-threatening consequences.

Here, RAMSIS offers defense organizations a way to model reality with precision. Engineers can simulate a wide range of pilot or operator body types, including variations in gear and protective equipment. They can analyze task-specific postures, reach envelopes, control accessibility, and visibility fields to ensure that every button, lever, and display is accessible under operational conditions.

This level of digital foresight is particularly valuable as defense systems evolve to include more advanced avionics, automation, and sensor suites. Every additional display or control adds complexity to the human-machine interface. Without ergonomic validation, there is a risk of overwhelming the operator or placing critical functions in suboptimal positions. RAMSIS helps ensure the interface is efficient, and safe under high-pressure conditions.

Beyond immediate mission performance, ergonomics also affects long-term health. Poor posture and repeated strain in cockpits or vehicles can lead to chronic injuries, reducing operational readiness. In fast jet aircraft, for example, improper seat design can exacerbate the physical toll of high-G maneuvers. Ground troops in armored vehicles face similar challenges from vibration, posture restrictions, and heavy gear. By integrating digital ergonomics into the design process, defense organizations protect both mission outcomes and the people who carry them out.

The ability to digitally test designs also accelerates development in a sector where timelines are often critical. New defense platforms must be field-ready as quickly as possible, yet traditional prototyping cycles can slow progress. RAMSIS supports a more agile approach, enabling engineers to validate ergonomics virtually and reduce late-stage surprises. That speed can be mission-critical in itself.

Shipbuilding: Sustaining Human Performance at Sea

Unlike cars or aircraft, ships are designed for long-duration human occupancy. Crews may spend weeks or months onboard, working and resting in the same confined spaces. In such environments, ergonomics is directly tied to safety, efficiency, and crew well-being.

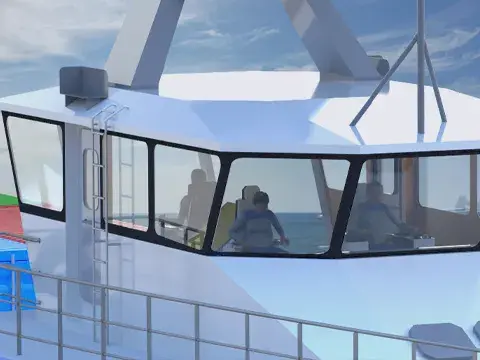

Bridge design is one of the most critical areas. Captains and operators must maintain clear visibility of the sea, navigation instruments, and critical controls for extended periods. Small oversights in sightlines or workstation layout can lead to fatigue, delayed reactions, or even accidents.

RAMSIS allows shipbuilders to simulate these environments with remarkable detail. Designers can test how operators of different sizes and nationalities will view the horizon from the bridge, whether they can reach essential controls without strain, and how confined quarters impact movement. Beyond bridges, RAMSIS can be applied to living quarters, machinery rooms, and workstations, anywhere humans interact with equipment.

By designing with real human diversity in mind, shipbuilders can reduce fatigue, improve safety, and enhance overall mission endurance at sea.

Modern ships are also becoming more automated, with advanced navigation systems and digital bridges reducing manual tasks. Yet even as automation grows, the human role remains central. Ergonomics ensures that operators can oversee these systems effectively, with interfaces designed to support quick understanding and decisive action. RAMSIS allows shipbuilders to validate not just physical comfort but also the perceptual accessibility of critical controls, helping crews maintain confidence and safety in increasingly complex vessels.

Why Digital Ergonomics is Rising Across Industries

What unites automotive, defense, and shipbuilding is not just the challenge of designing interiors; it is the growing recognition that traditional methods are no longer enough.

Physical prototypes and mock-ups are costly, time-consuming, and limited in scope. They cannot capture the full spectrum of human diversity, nor can they be easily adjusted once flaws are discovered. In contrast, digital ergonomics offers an agile, cost-effective way to test designs against thousands of real-world scenarios before any material is cut.

RAMSIS stands out because it is not simply a computer-generated mannequin. It is built on decades of anthropometric research, with body data collected from populations around the world, and of behavior research, with postural data collected in various vehicle types and situations. This makes RAMSIS a true digital twin of human diversity, allowing engineers to account for differences in body shape, posture, and biomechanics with scientific accuracy.

The trend is clear: as industries face pressure to reduce costs, accelerate timelines, and meet higher standards of safety and inclusivity, digital ergonomics is becoming indispensable.

Interested in More Content Like This?

Subscribe to the Humanetics Pulse newsletter to learn more about Humanetics Products, News, and Industry Updates.

Designing for Every Body

Across all applications, the principle remains the same: the human must remain at the center of design.

Automotive engineers can no longer afford to design for the “average” driver. Defense organizations cannot risk cockpits that only fit a narrow range of pilots. Shipbuilders cannot overlook fatigue in long-duration missions.

RAMSIS provides a shared solution, ensuring that technology adapts to people, not the other way around. By bringing diverse, data-driven human models into the earliest stages of design, engineers can build vehicles that are safer, more inclusive, and better suited to their mission.

This is not only about efficiency. It is about fairness, performance, and safety. It is about ensuring every body has a place at the controls, in the seat, or on the bridge.

The Future of Ergonomic Design

Looking ahead, the role of digital human modeling will only expand. As vehicles become more automated and human-machine interfaces evolve, the way people interact with technology will continue to change. Ensuring that these interactions are seamless, safe, and inclusive will be a defining challenge of the next generation of design.

Whether in a self-driving car, a next-generation fighter jet, or an advanced naval vessel, the measure of success will not only be the sophistication of the technology, it will be how well it fits the people who use it.

With RAMSIS, industries have the tools to meet that challenge. By keeping ergonomics mission-critical and human-centric, they are reshaping the future of cockpit and cabin design.

Speak to an Expert

Fill out the below form and one of our experts will contact you.

Dr. Hans-Joachim Wirsching

Dr. Hans-Joachim Wirsching is a Senior Product and Project Manager for Ergonomics at Humanetics, with over 25 years of experience in developing digital ergonomic simulation applications. He specializes in integrating methods and models into the ergonomic design tool and digital human model RAMSIS, combining scientific knowledge with the practical requirements of vehicle engineers. Hans-Joachim is also an active member of the digital human modeling community, contributing conference papers and presentations that address new developments and applications of RAMSIS.