Crash safety technology has advanced dramatically, but some people are still left behind.

Over the last five decades, vehicle safety systems have become smarter, stronger, and more sophisticated. Yet despite these improvements, many crash tests still rely on models that do not represent the full range of human bodies on the road.

Traditional crash tests focus on meeting standards, not capturing human variability. While physical and digital crash test dummies provide valuable data, they are designed around a narrow demographic, typically the average-sized male in an upright seated posture. That leaves women, older adults, children, and people in non-traditional seating positions underrepresented in safety evaluations.

It is time to shift from compliance to real-world protection. Automotive engineers must start asking not just “Did the car pass the test?” but “Who are we protecting and how effectively?” This means going beyond threshold-based metrics to understand injury risk in a deeper, more human-centered way.

Crash Testing Has Saved Lives, but It Has Blind Spots

There is no denying the progress. Crashworthy structures, advanced airbags, and precision restraint systems have all contributed to a steep decline in crash fatalities. Much of that progress is thanks to decades of physical crash testing using anthropomorphic test devices (ATDs), which remain essential to vehicle design.

But these tools have limits. ATDs provide reliable and repeatable measurements, but they do not reflect the wide range of human shapes, postures, or biomechanical responses seen in real-life crashes.

Meeting regulatory thresholds is not the same as preventing injury. Injury risks differ greatly between individuals. Bone density, body size, age, posture, and muscle tone all affect how the human body responds in a crash. Current testing does not fully account for this variation.

The Human Body Reacts in Complex Ways During a Collision

A crash sets off a chain reaction inside the body. When a vehicle suddenly decelerates, the internal organs continue to move. Seatbelts may restrain the torso, but the head snaps forward. The neck compresses and rebounds. Limbs swing and twist, often violently.

Injuries go deeper than broken bones. Tissue damage, nerve injury, and internal organ trauma often occur beneath the surface. These injuries depend not just on impact force but on how the body absorbs and distributes that force.

One-size-fits-all dummies cannot tell the full story. Most crash test dummies do not account for anatomical variation or tissue behavior. That makes it hard to predict or prevent complex injuries, especially for people outside the 50th percentile male standard.

Traditional Crash Test Dummies Provide Value but Not Full Insight

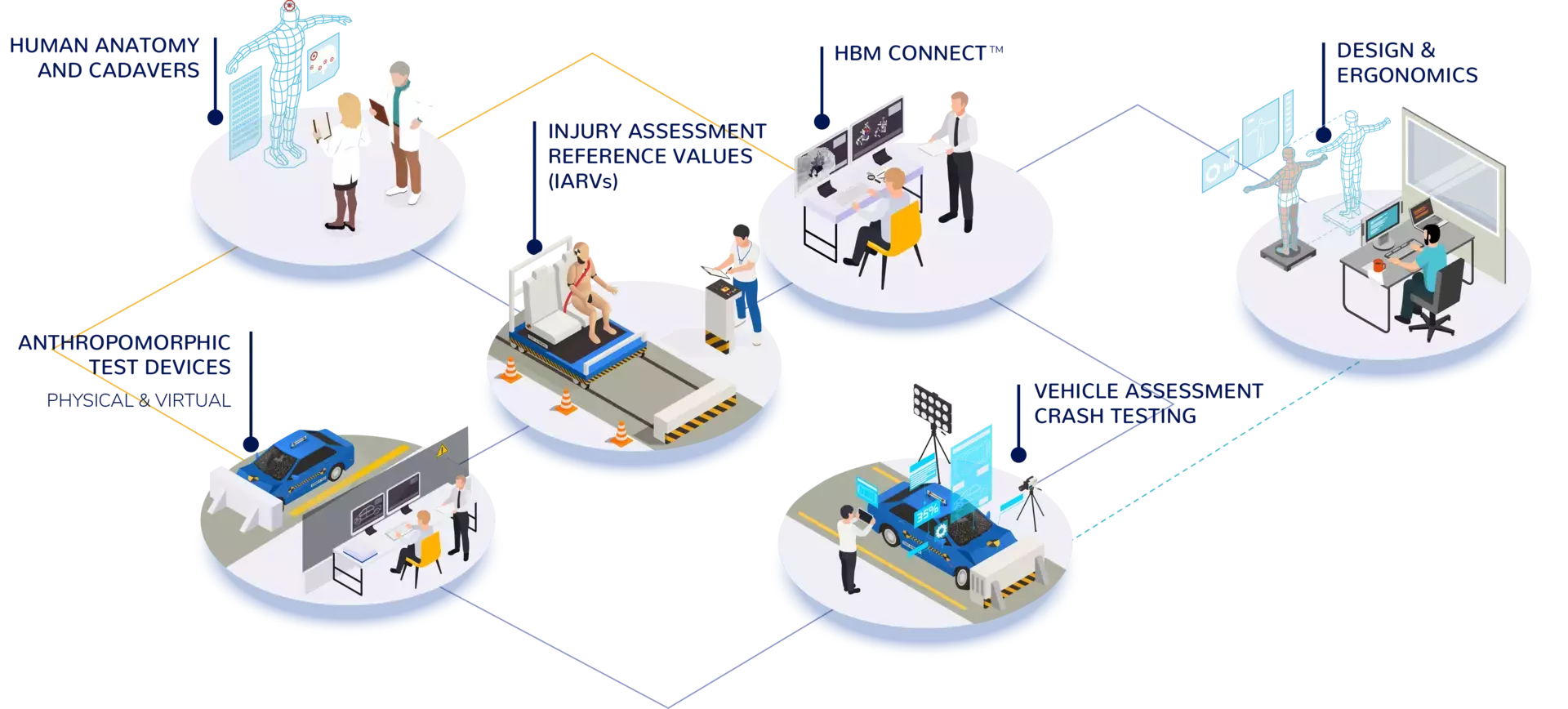

ATDs are among the most important safety tools ever created. They allow engineers to standardize tests, benchmark performance, and comply with regulatory limits. Physical ATDs, paired with digital counterparts, are foundational to automotive crash safety.

But they are built around averages. The typical dummy represents an average adult male in an upright position. This limited model helps answer questions like, “Did chest compression remain below the regulatory threshold?”

They do not model the internal response of the human body. ATDs do not simulate how a smaller or older body reacts to force. They do not replicate soft tissue, organ movement, or the complexity of spinal loading in reclined or rotated seating positions.

They are necessary but incomplete. To fully understand injury risk, we need more than mechanical surrogates. We need tools that reflect real human bodies in real crash situations.

Real People Are Missing From The Safety Equation

Certain groups are at significantly higher risk of injury. Studies show that women are more likely to be seriously injured in frontal crashes, even when wearing seatbelts. Older adults face increased spinal and chest injuries due to changes in bone and tissue properties. Children react differently to impact forces due to their proportions and developmental stages.

These are not edge cases. They are a significant share of today’s drivers and passengers. Designing only for an average male means failing to protect the full population.

Lack of data leads to lack of protection. Without inclusive testing, vehicle designs may leave these people less protected, not because of intent, but because of unrepresented information.

Crash Testing Must Evolve to Understand Injury Mechanisms

Regulatory tests provide binary outcomes. Did the vehicle pass? Did the dummy stay within limits? These yes-or-no answers do not capture the nuances of real-world injuries.

Human injuries are not binary. People may walk away with no fractures but suffer chronic pain or soft tissue damage. Injury depends on how the body moves, bends, and absorbs force—not just on hitting a number.

A deeper understanding is needed. To improve safety, we must look beyond pass or fail and explore why injuries happen and how they can be prevented. That requires a new type of model.

Human Body Models Offer a More Complete Picture

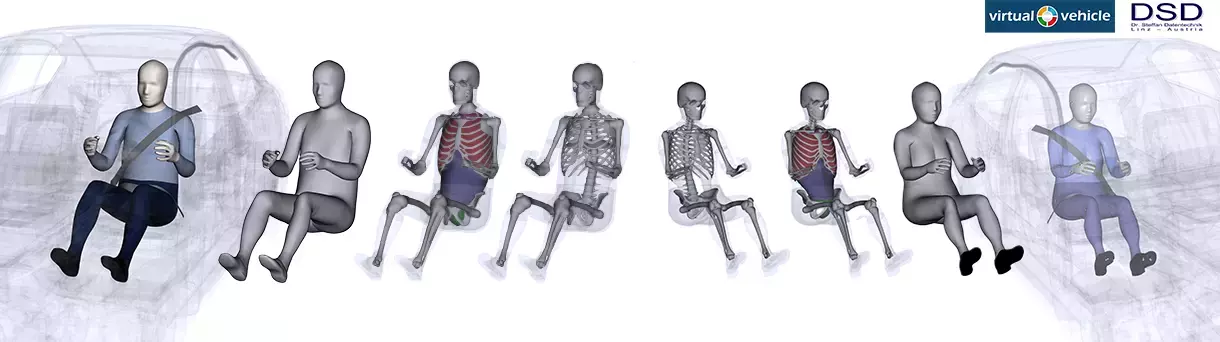

Human body models (HBMs) are digital simulations of real human anatomy. They include bones, muscles, ligaments, organs, and joints. These models go far beyond the geometry of a crash test dummy to reflect the internal complexity of the human body.

HBMs help engineers simulate real injuries. They can predict how the spine compresses, how organs shift under impact, and how different body types respond to collisions. This level of detail is critical for designing safety systems that work for everyone.

Advanced scaling makes HBMs adaptable. Engineers can adjust HBMs for different ages, sizes, and postures. This enables scenario-specific simulations that mirror real-world crash conditions.

Human Body Models Help CAE Teams Improve Safety Outcomes

Computer-aided engineering (CAE) teams benefit from HBM integration. These models allow for earlier and more comprehensive safety evaluations during design. They help connect virtual simulations to real-world injury outcomes.

HBMs reveal risks traditional tools may miss. When used alongside ATDs, human body models offer a deeper layer of validation. They help refine safety features like seat geometry, belt pretensioning, airbag placement, and cabin layout.

Emerging vehicle designs require new tools. Electric and autonomous vehicles are changing how occupants sit and move. Simulating these new positions and interactions requires models that can reflect those dynamic realities.

Interested in More Content Like This?

Subscribe to the Humanetics Pulse newsletter to learn more about Humanetics Products, News, and Industry Updates.

Combining Human Body Models and ATDs Creates a Complete Approach

Human body modeling does not replace ATDs—it complements them. Physical and digital crash test dummies will remain essential for regulatory and validation testing. But HBMs provide the detail and variability that ATDs cannot.

Together, these tools offer a fuller picture of crash safety. They allow for more inclusive design, more informed decision-making, and better protection for all passengers.

The future of crash safety is not just mechanical—it is human. By adding depth to our testing toolbox, we move from compliance to compassion. We build for the reality of injury, not just the boundaries of the test.

Embracing a Human-Centered Future in Automotive Safety

The definition of safety is changing. It is no longer enough to pass a test or meet a standard. Today’s safety engineering must account for who is in the vehicle, how they sit, and how their bodies react.

Real safety is inclusive and adaptive. It protects children and adults, men and women, young and old. It reflects diversity in body type, physiology, and biomechanics.

Crash testing must evolve to meet this need. With tools like human body models, engineers can build vehicles that better understand injury risk—and better protect people in the process.

This is more than technology. It is responsible design. By focusing on the human experience, we create safer, smarter vehicles. And we take the next step in making automotive safety truly universal.

Speak to an Expert

Fill out the below form and one of our experts will contact you.

Chirag Shah, PhD, PMP

Chirag is the CAE Product Development Manager, where he leads strategy, planning, and execution for Human Body Model (HBM) initiatives. With more than 16 years of experience in the automotive sector, he specializes in technology integration, project and product management, and cross-functional collaboration, driving innovation in virtual modeling solutions that enhance safety and performance outcomes.