Modern trucks carry more than cargo—they carry the weight of responsibility.

Truck safety is a critical focus for the automotive industry as regulatory bodies and organizations aim to reduce road fatalities and improve the protection of all road users.

With the rise of advanced driver assistance systems (ADAS) and stricter safety regulations like UNECE R151 (Blind Spot Information System) and R131 (Advanced Emergency Braking System), manufacturers face increasing pressure to ensure their vehicles meet these standards.

Accurate and repeatable testing is essential to verify these safety systems, and advanced robotic platforms like Humanetics' UFOs and DRm Driving Robots play a crucial role in this process.

When Size and Safety Collide: The ADAS Dilemma

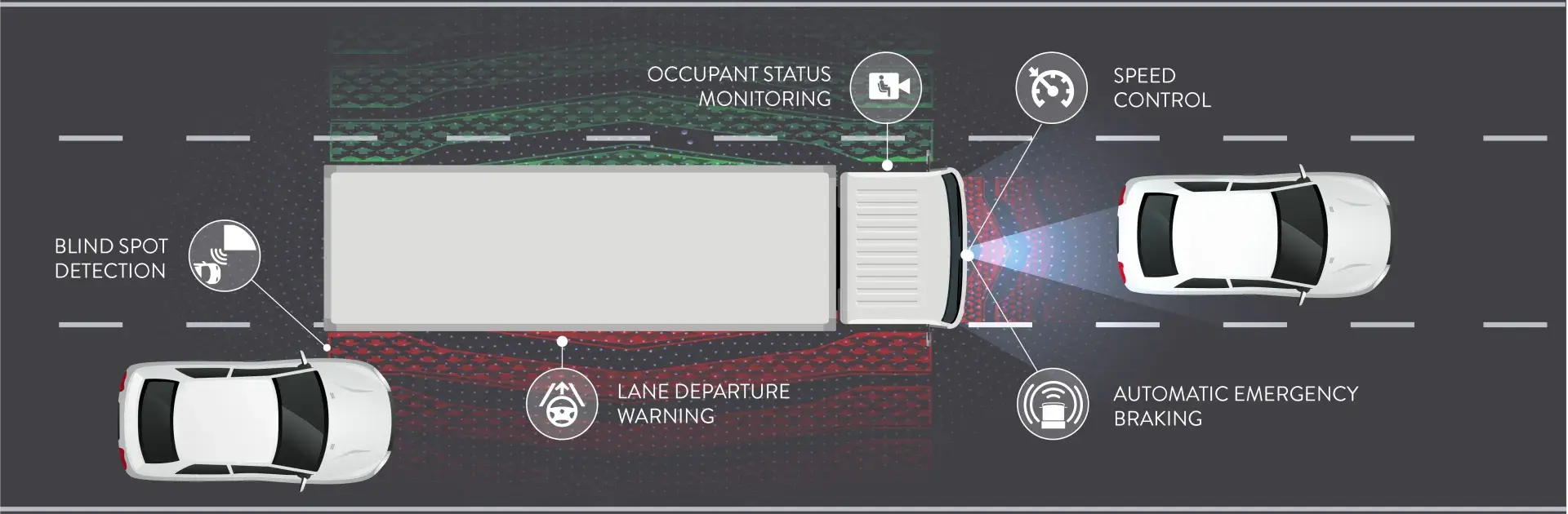

One of the main challenges in truck safety is the complexity of modern ADAS technologies and their integration into large vehicles.

Systems such as automatic emergency braking (AEB), blind spot detection, and lane-keeping assist must perform reliably under diverse conditions. The size and limited maneuverability of trucks make it difficult to ensure consistent detection of pedestrians and other vehicles.

Adapting to changing regulations adds further complexity. For example, UNECE R131 primarily applies to heavy-duty vehicles, mandating the use of Autonomous Emergency Braking (AEB). R151 requires blind spot monitoring systems. Meanwhile, newer regulations like R152—focused on passenger vehicles—mandate AEB for cars and light commercial vehicles, while R159 introduces Moving-Off Information Systems (MOIS) to protect vulnerable road users around heavy vehicles.

These evolving standards demand precise and repeatable testing to validate robust ADAS solutions.

From Theory to Asphalt: The crucial role of real-world adas testing

To overcome these challenges, manufacturers must adopt advanced testing methodologies that reflect real-world conditions.

Accurate ADAS testing requires consistency across different environments, from urban settings to high-speed scenarios. By replicating complex driving situations, manufacturers can identify system vulnerabilities early, improve safety performance, and ensure compliance with evolving regulatory standards.

This systematic validation approach is crucial as regulations increasingly emphasize protecting vulnerable road users and enhancing truck operational safety.

ADAS testing for trucks involves a range of standardized assessments to verify system performance and regulatory compliance.

Key tests include automatic emergency braking (AEB) scenarios, where trucks must detect and respond to stationary and moving objects, including pedestrians and cyclists. Blind spot detection tests evaluate a vehicle's ability to identify and alert drivers to hidden road users during lane changes or turns.

Lane departure warning and lane-keeping assist tests ensure trucks maintain their intended path and can correct unintended deviations. Additionally, moving-off information system (MOIS) tests validate a truck’s ability to detect pedestrians in front of the vehicle when starting from a stationary position.

These comprehensive tests are essential to verify the accuracy, reliability, and responsiveness of safety systems before they are deployed on public roads.

Want to Read More?

Subscribe to the Humanetics Pulse newsletter to learn more about safety as a mission and the full ecosystem.

The Key to Effective Validation: Robust and Reliable Testing Solutions

Driving robots play a crucial role in ADAS testing by ensuring the precise and repeatable execution of complex driving maneuvers.

The Humanetics DRm Driving Robot provides accurate control of steering, braking, and acceleration, which is essential for meeting the strict requirements of regulatory tests. This level of precision is critical for replicating real-world scenarios where human variability can impact test outcomes.

With programmable, repeatable motion, the DRm enables consistent testing of critical ADAS features across a wide range of scenarios, including high-speed lane changes and emergency braking.

The Humanetics DRm offers rapid installation, typically completed within 30 minutes, providing one of the fastest and easiest setup processes available among driving robots. Its compatibility with a wide variety of vehicles and vehicle sizes makes it flexible and practical in ADAS testing applications.

Performing durability tests helps identify potential failures before vehicles reach consumers, enhancing overall road safety. The Humanetics DRm supports these rigorous tests by providing precise and repeatable control over demanding maneuvers, including the fishhook test—a critical evaluation for vehicle stability and rollover prevention.

The fishhook test is particularly important for assessing how trucks and other heavy vehicles respond to sudden steering inputs, helping manufacturers comply with regulatory standards and ensure vehicle safety.

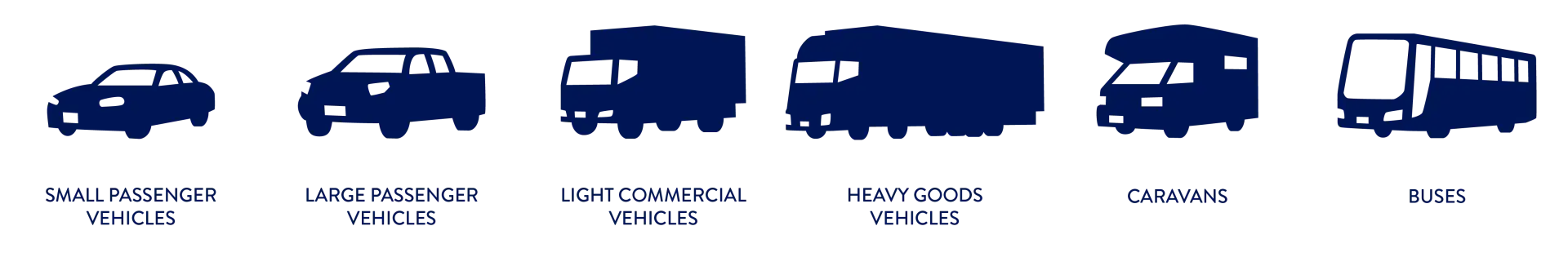

One of the key advantages of the DRm is its versatility across a wide range of vehicle types. It is compatible with trucks, caravans, buses, and passenger vehicles, offering a flexible solution for manufacturers testing diverse fleets.

This adaptability allows for comprehensive testing across different vehicle platforms without requiring extensive modifications, making it ideal for misuse tests, durability evaluations, and stability assessments like the fishhook test.

The DRm is also designed with user-friendliness in mind.

Its intuitive installation process and straightforward operation minimize setup time and reduce the complexity of integrating advanced driving automation into ADAS testing.

This ease of use allows engineers to focus on the accuracy and efficiency of their testing programs while maintaining compliance with evolving regulatory standards.

With its robust design and flexible capabilities, the Humanetics DRm provides the precision and reliability required for comprehensive ADAS testing, including the most demanding misuse and durability tests.

Speak to our experts

Fill out the below form and one of our experts will contact you

Markus Schmidl

Markus Schmidl joined the Humanetics team in 2012 with the goal of taking a thorough look at the product offerings and answering the question – how can we make these products even better than they already are? With his background in printing press machine sales at Heidelberger, Markus already knew that in a machine-driven workflow, maximum efficiency is critical to success.