Elevate your ATD Laboratory

Automation and connectivity are not only megatrends in today’s high-tech world, but are also the foundations of the Connected Lab. An essential part of this is the new ATD-BaseWare<small>™</small>. Our ATD-BaseWare<small>™</small> embodies and elevates the concept of the digital and connected dummy laboratory. The ATD-BaseWare<small>™</small> operating system is a key component of all our configurations, powering functions like the automatic live display of measured data, the ISO MME evaluation tool, and the dummy report generator. By using cloud computing and artificial intelligence, the in-dummy-DAS can be managed easily and component failure can be predicted more precisely.

The ATD-BaseWare<small>™</small> works as a control system for Next Gen Test Systems as well as third-party systems, and systems with TCP/IP connection and available SDK’s. Sensor data and settings such as the next calibration date, sensitivities, ISO codes can be easily updated. With the implemented notification management, the user receives automatic notifications if a sensor is e.g. due for its next calibration, facilitating planning.

Due to supporting ISO 17025 and TISAX 5.0 (Trusted Information Security Assessment Exchange) conform testing, the creation of conforming data is possible by preventing data manipulation through extensive user management, assignment of authorizations, and logging of activities. Additionally with the usage of the ATD-BaseWare<small>™</small>, lab-to-lab variability is reduced with its remote connectivity. This allows a global cooperation between OEM‘s, regulatory agencies, independent test facilities, consortiums, universities, and more.

The ATD-BaseWare<small>™</small> offers a closed-loop process with a single user interface for acquiring data, conducting analysis, and generating a report. Compatibility with different DAS systems is easily possible.

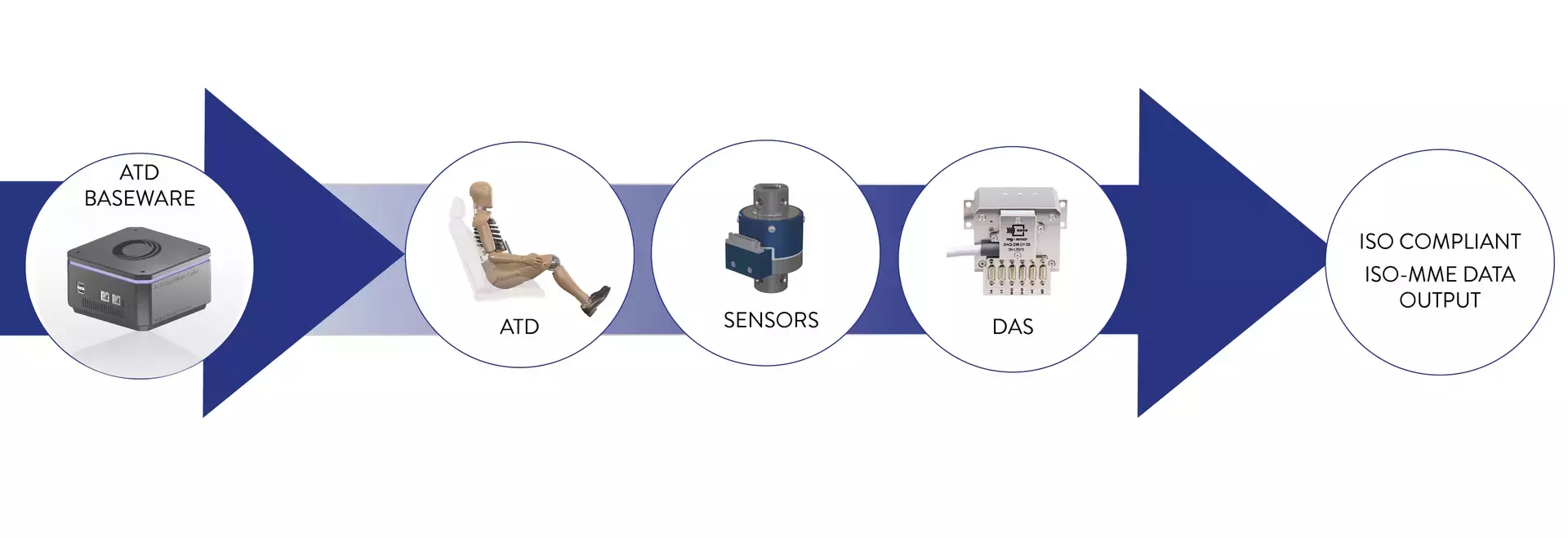

After the data is acquired through the ATD, its sensors, and the data-acquisition system, it is being automatically processed afterwards in the software and ISO-MME data generated. Due to the closed-loop process, the data output generated is repeatable and reproducible.

Connected products

Contact Us

Let us know how we can help

Access Our Service & Support Portal

Please submit any software-related service and support requests through our support portal.